Table of Contents

Case information

Tooth position: Mandibular edentulous jaw & implant #46, #44, #42, #32, #34, #36.

Implant system: #32. #42 Nobel, #34. #36. #44. #46 Dentium

Restoration type: Toronto bridge

Material: Titanium

Superstructure type: 34-44 ceramic crowns, 35-36, 45-46 Solidex crowns

Color: #32-42 A2, #33-36 & #43-46 A3

Case source: Shenzhen Jiahong Dental Medical Co. LTD

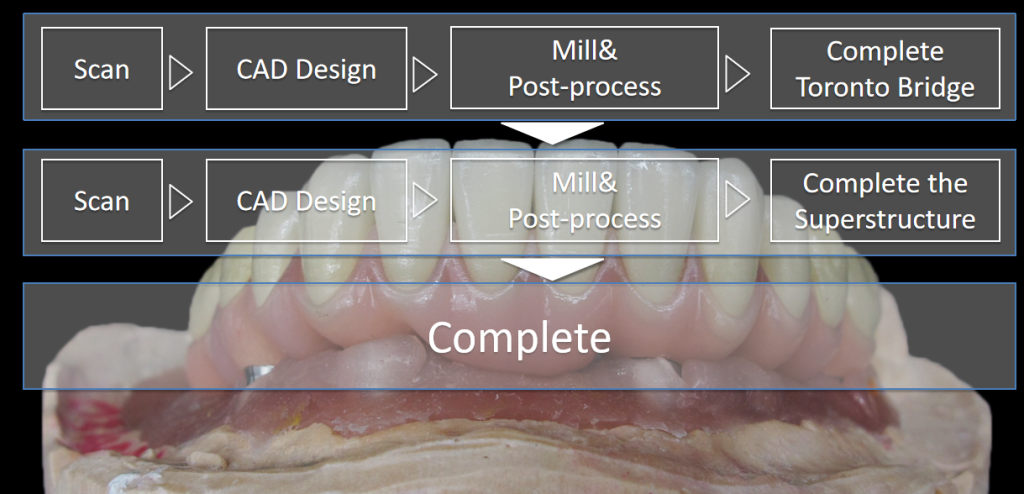

Workflow

Step 1. Make Toronto Bridge

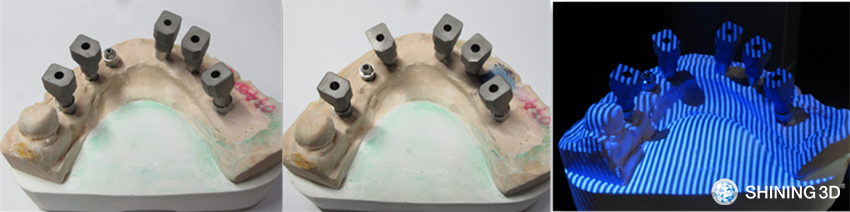

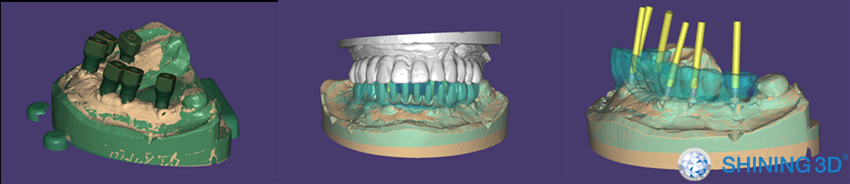

1.1 Scan with AutoScan-DS-MIX

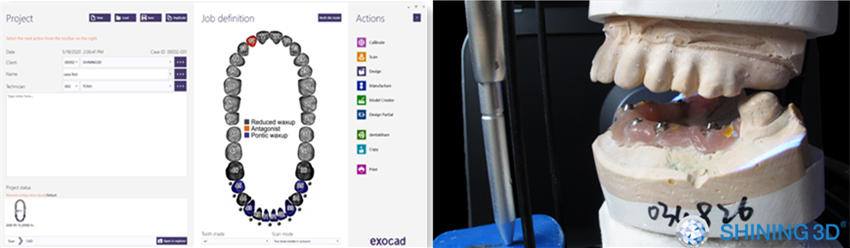

Create an order in the scan software.

Scan the model with AutoScan-DS-MIX dental 3D scanner.

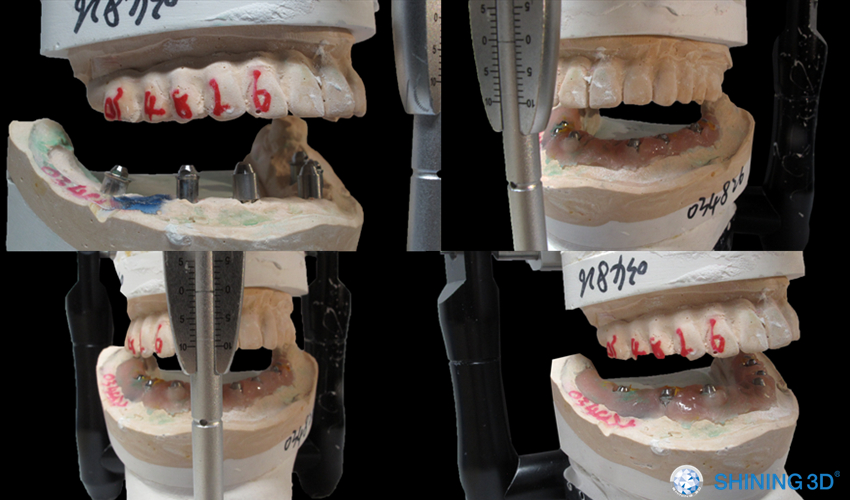

Due to the large angles of 32 and 34, the scan bodies can be collided with each other. So install the scan body of 34 first and scan. Then replace it and install scan body of 32 and get all the data with multiple add-scan. (See pictures below.)

AutoScan-DS-MIX’s exceptional scan performance, featuring 2*5.0MP high resolution and ≤7μm high accuracy, guarantees reliable scan result, which will largely improve the design & production efficiency.

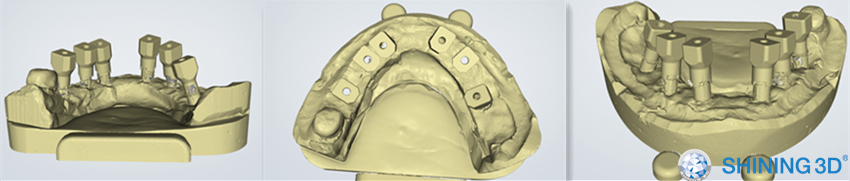

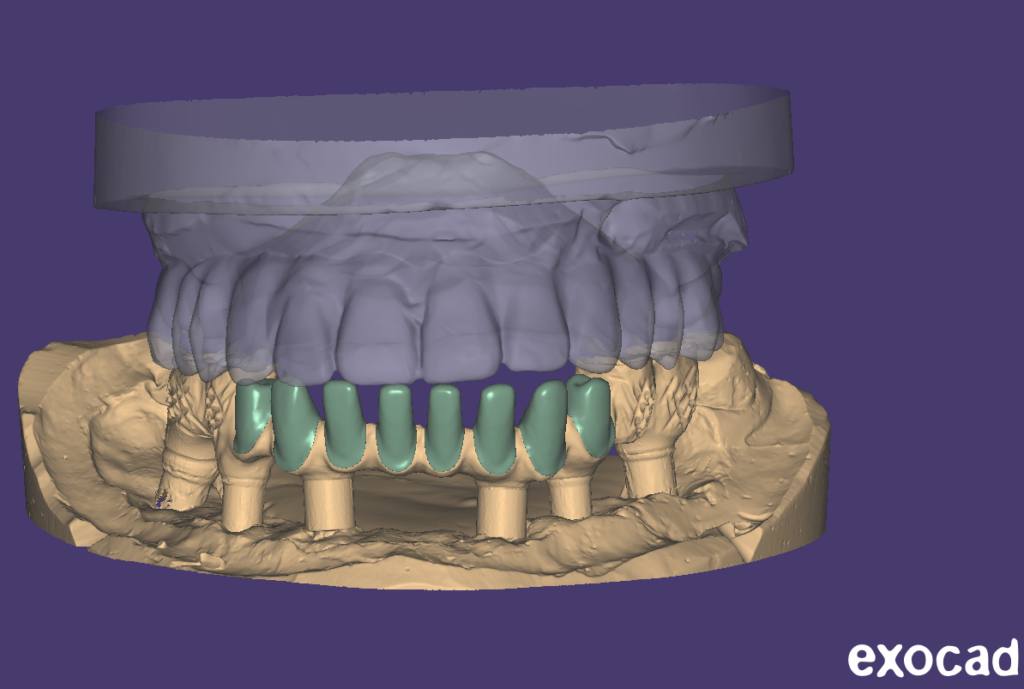

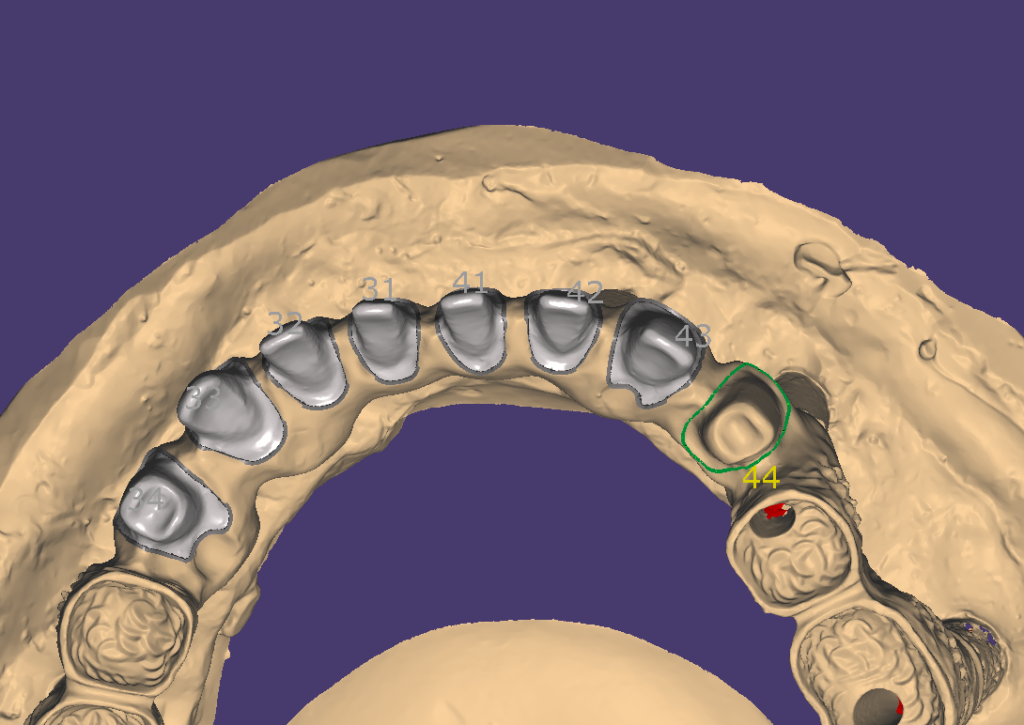

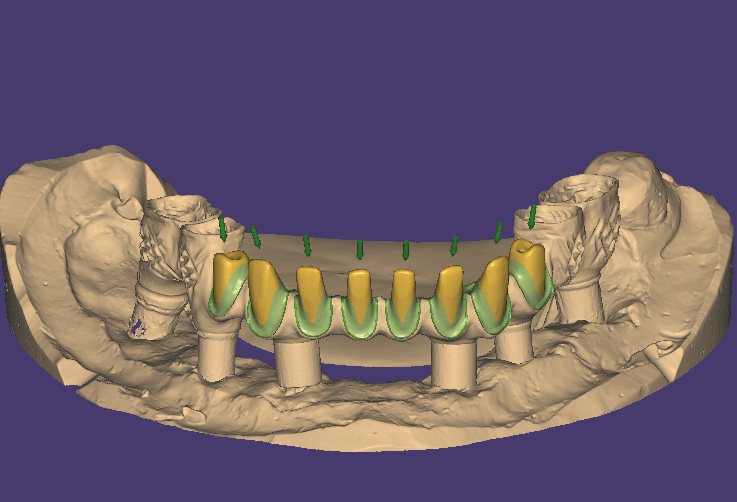

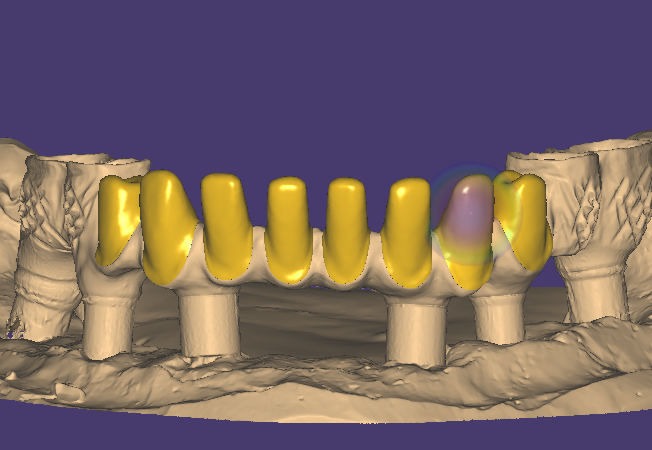

1.2 Design in exocad

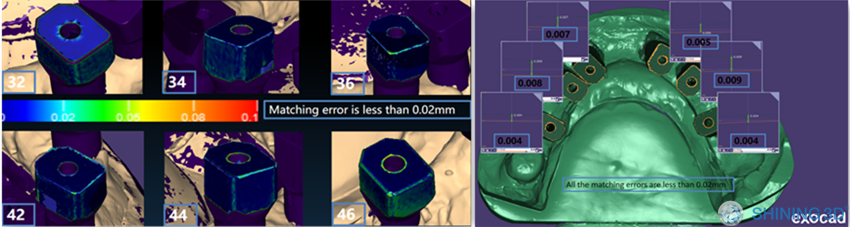

It can be seen from the color bar the matching error is less than 0.02mm.

Design the Toronto bridge in exocad.

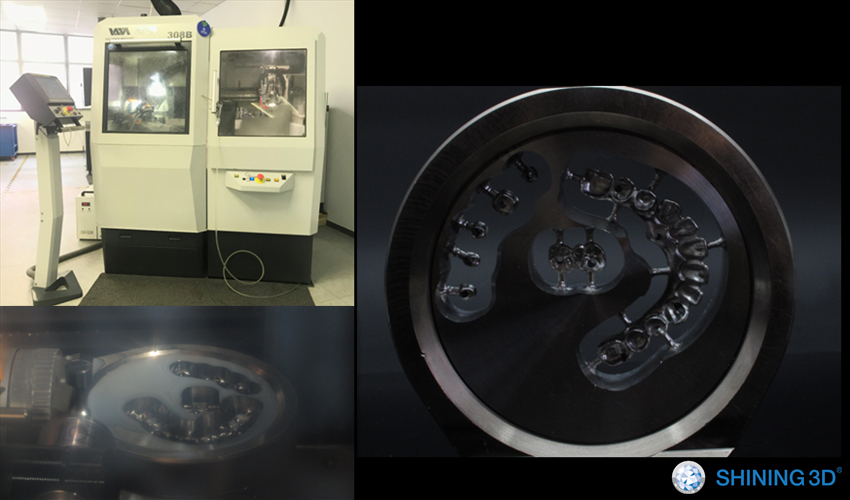

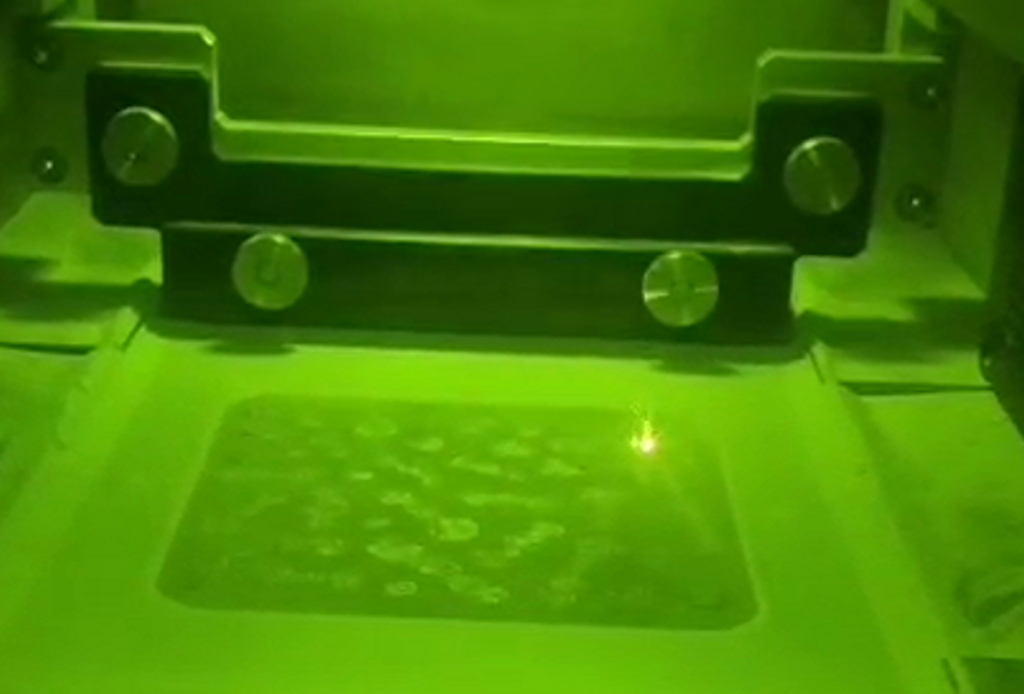

1.3 Milling

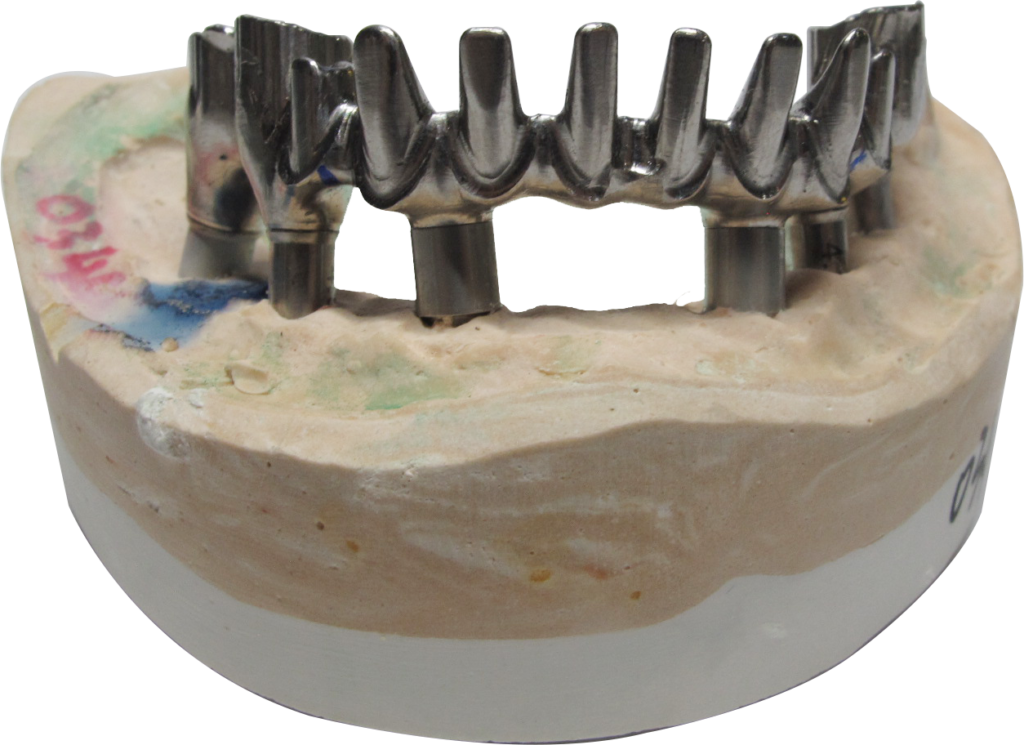

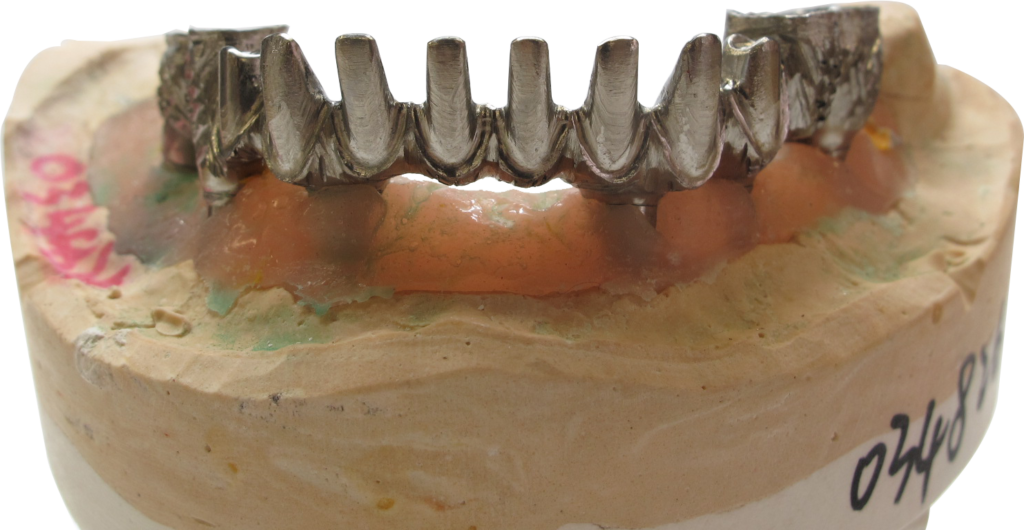

1.4 Complete Toronto Bridge

Based on ideal scan result with excellent CAD designing and milling, the bridge fits perfect on the model. The picture shows the fit situation with only one screw assembled.

3D Scan to Create a Toronto Bridge with Superstructures

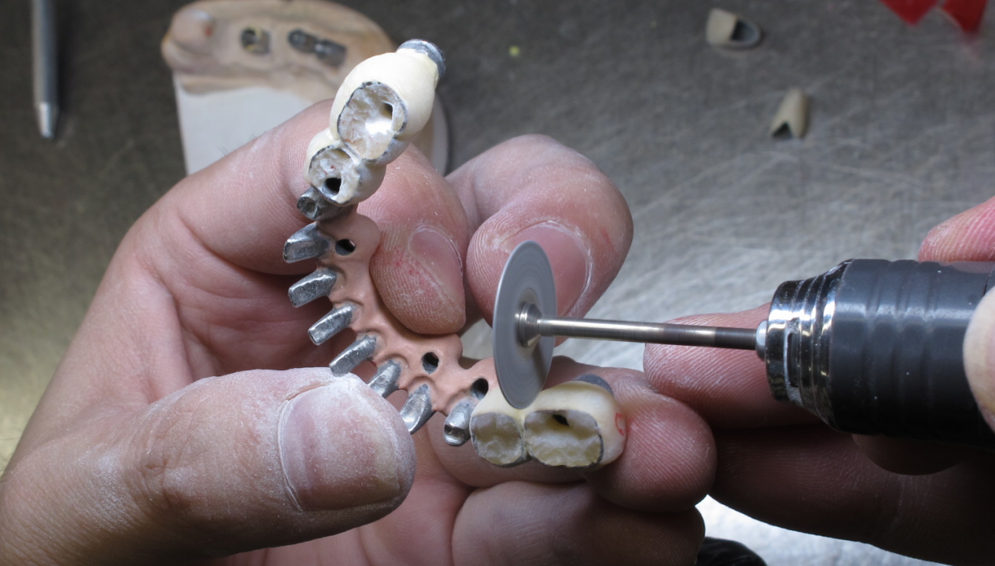

1.5 Post-processing of Bridge

Try-in

Metal grinding

Build up opaque

Step 2. Make the Superstructure

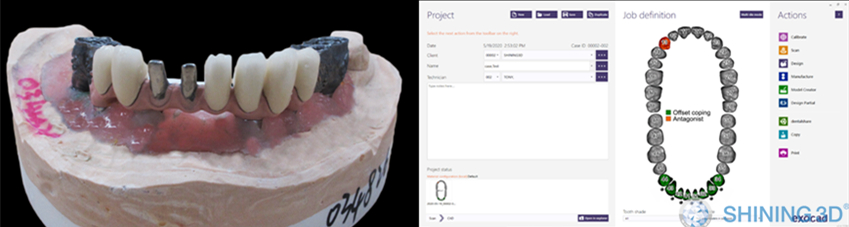

2.1 Create an order for superstructures

#34–#44 are PFM crowns.

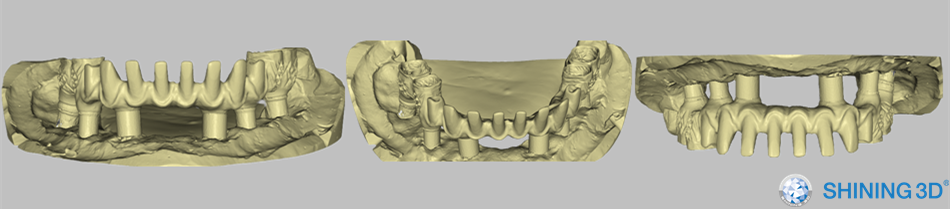

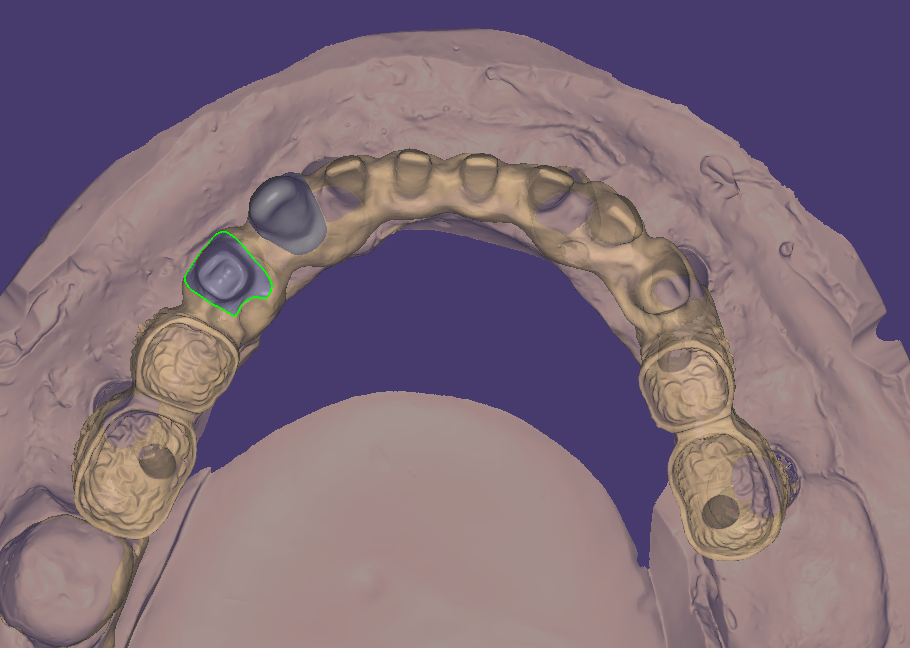

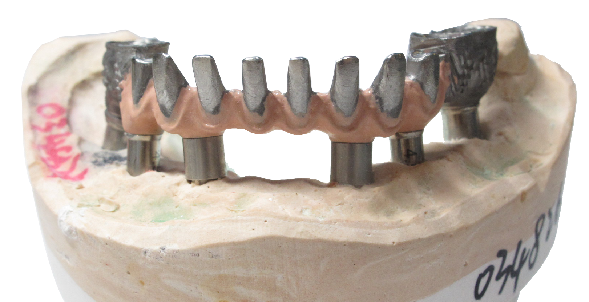

2.2 Scan Toronto Bridge

Scanning with AutoScan-DS-MIX, all the details were perfectly kept.

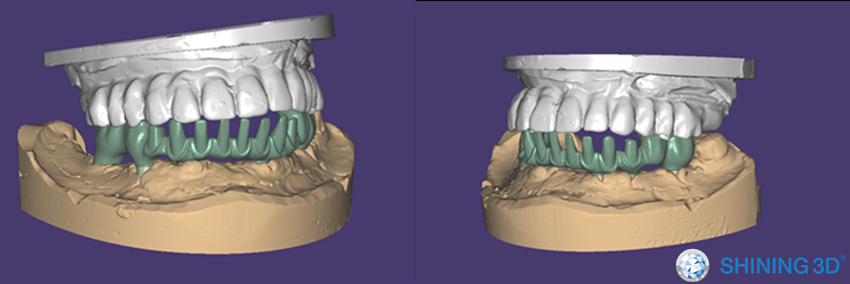

2.3 CAD Design with exocad

Design copings from #34-#44

2.4 Post-processing of Superstructures

Printing & grinding for copings

Ceramic building & grinding

Complete solidex

Complete gingiva

In this case 34-44 were ceramic crowns, 35-36, 45-46 were solidex & gingiva.

3. Completion

Using 3D Scanning to Create a Toronto Bridge with Superstructures

The AutoScan-DS-MIX high-end dental lab 3D scanner developed by SHINING 3D convinces users with its open design and modular structure featuring fine details, high accuracy as well as high efficiency fulfilling users’ demands of a wide range of applications including but not limited to crowns & bridges, abutments, bars, etc.

ENG

ENG