Table of Contents

As digital technology becomes widely used and takes root in the dental field, an increasing number of dentists are switching from conventional treatment to digital one worldwide. Digital technology plays a positive role in promoting oral aesthetics implant restoration and improving treatment efficiency. Toady’s case is talking about the digital single arch implant restoration.

In Egypt, Dr Abdelrahman Khalaf and Dr Kirollos Hany from the Faculty of Dentistry at Assiut University have been promoting the use of digital technology in dentistry for years. They hope to provide patients with more accurate diagnoses, a more comfortable treatment process and better treatment results through advanced equipment. Today’s case is a typical application of digital technology in the field of oral implants, making the complex treatment process simple, controllable, comfortable and efficient.

Background

The male patient was 42 years ago. Though he is young, he suffered from an edentulous upper arch and had only 7 anterior teeth in the lower jaw with severe gingival recession. This poor oral condition led to masticatory problems and an inability to eat, resulting in a decrease in his quality of life. After struggling with this problem for a long time, the patient turned to Dr Abdelrahman Khalaf and Dr Kirollos Hany for help, hoping to restore the function of oral chewing and have beautiful teeth. Taking the patient’s wishes, oral conditions and existing technology into consideration, Dr. Abdelrahman Khalaf and Dr. Kirollos Hany designed a digital implant treatment for the patient after the clinical and radiographic examination.

Design and manufacture of implanting guide plate

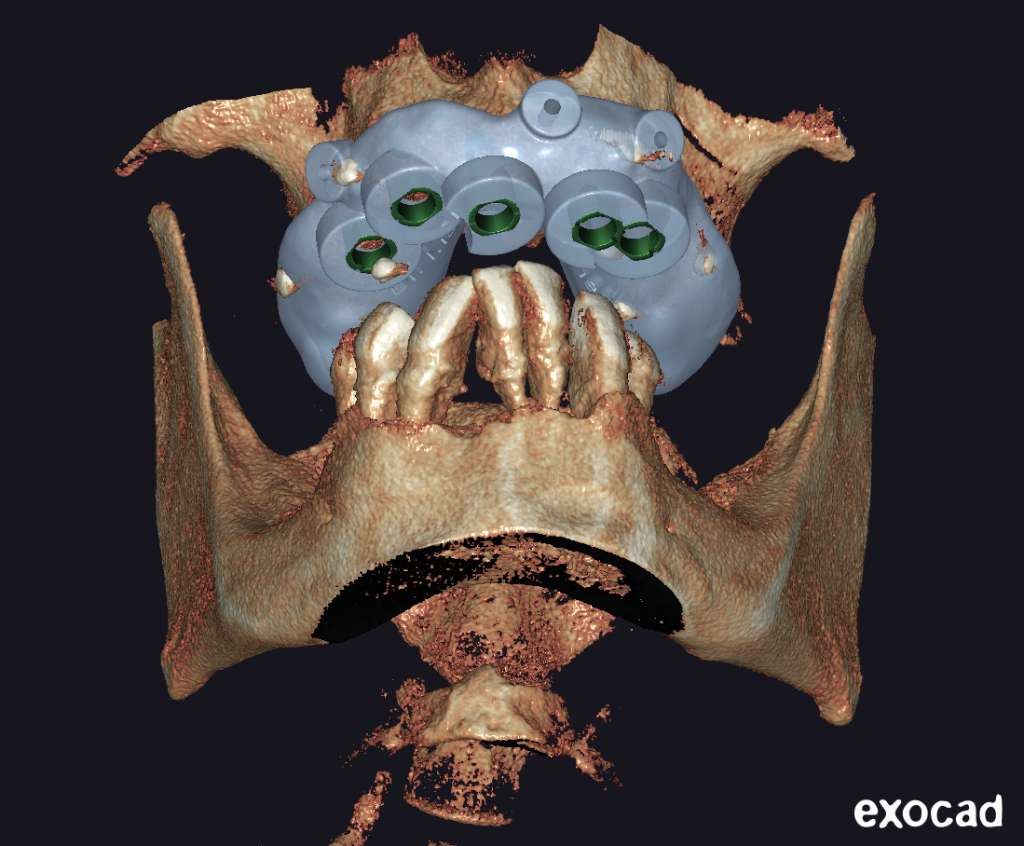

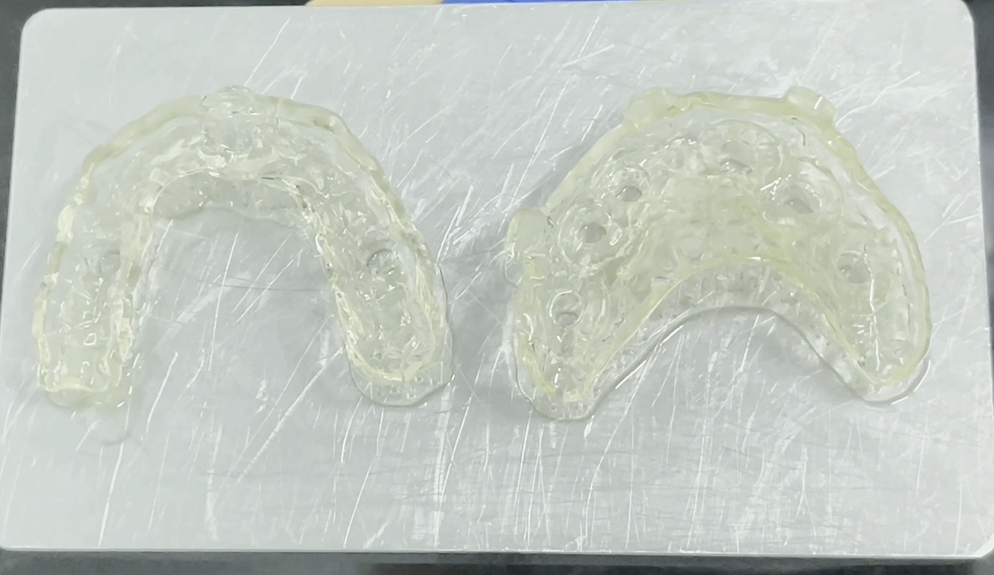

Digital implanting is to help us complete the implanting surgery better with the help of digital technology. The first step of implanting surgery is pre-op diagnostic and virtual implanting. Dentists can simulate dental implants in the design software. According to the thickness of the alveolar bone and bone plate, the implant angle and depth can be set in advance, and the implant guide plate is designed as well. The implant guide plate can accurately locate and guide the whole implanting surgery, avoiding the most common problems, such as side wall perforation, poor implant position, direction and depth. The restoration-oriented implanting guide plate design guides the appropriate position of the implant body and makes the final aesthetic effect good. With the assistance of an implant guide plate, dentists can complete multiple implants in one surgery at higher efficiency. All these have greatly improved the success rate of implant surgery.

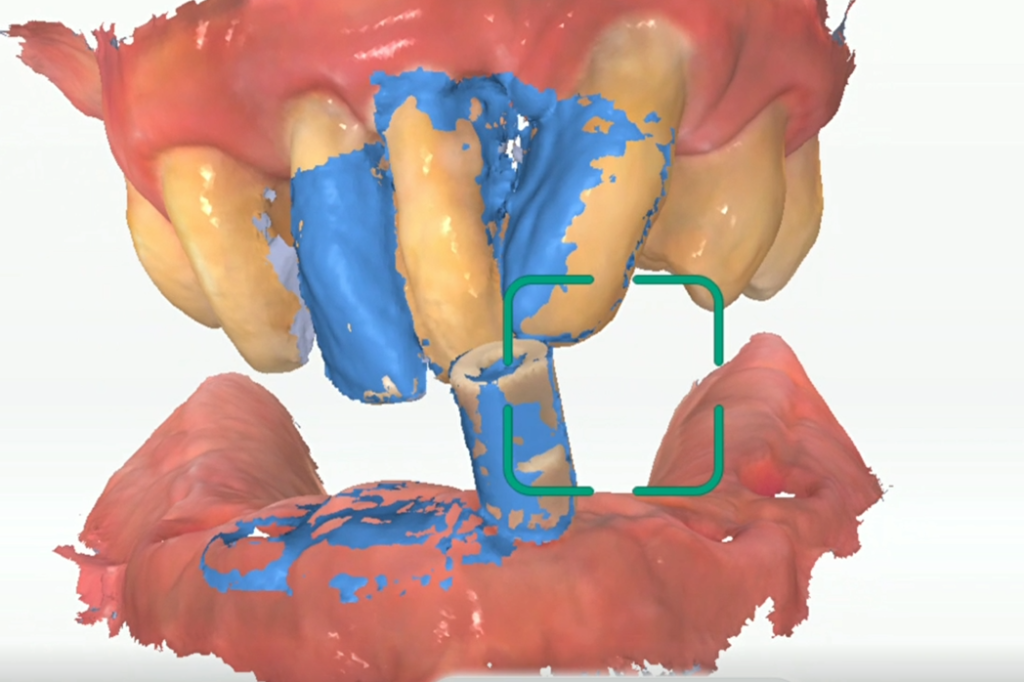

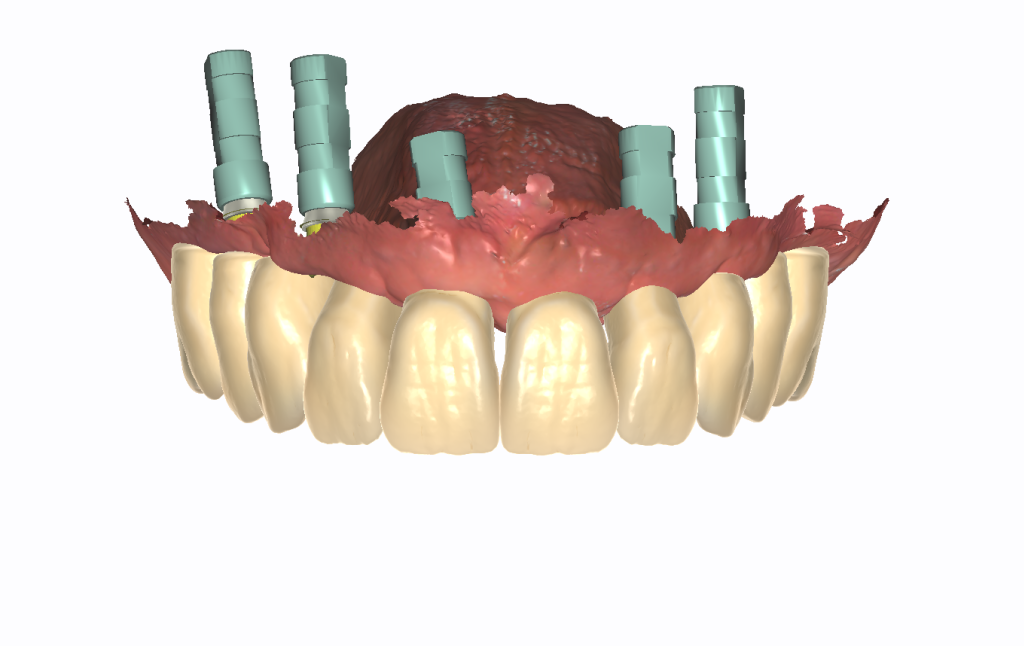

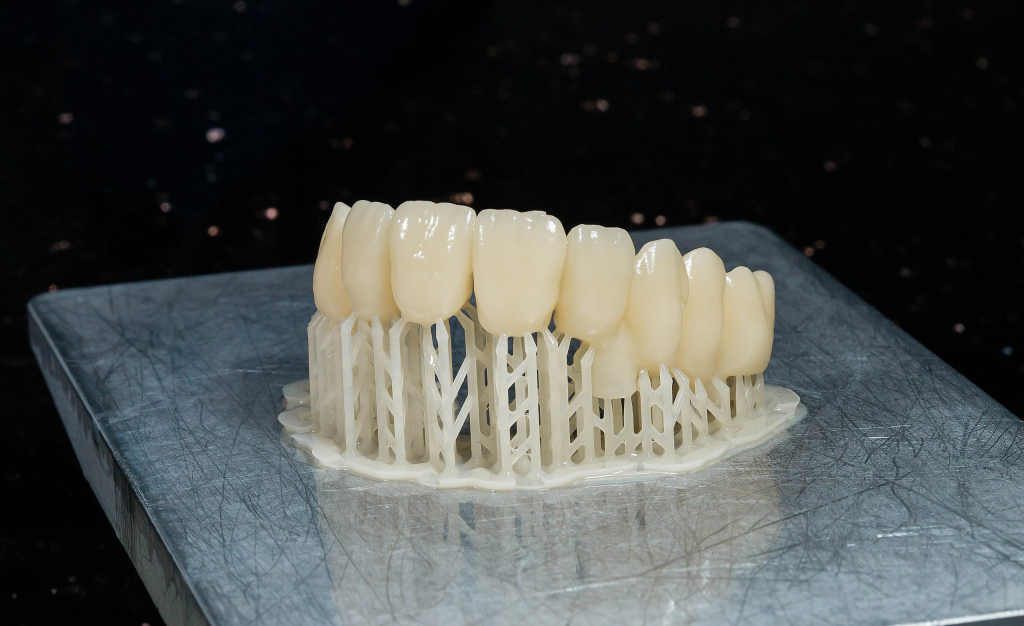

In this case, Dr Abdelrahman Khalaf and Dr Kirollos Hany tried their best and preserved all the patient’s dental tissue of the lower jaw after a comprehensive assessment, decided to go for All on 5 as the patient refused to do any bone augmentation or sinus left, and designed an implant guide plate through dental software, make the implant position at #11, #12, #14, #22, #24. The designed implant guide plate was printed out by AccuFab-D1s from SHINING 3D using SG01 photosensitive polymer resin and can be used directly for implant surgery. AccuFab-D1s is a printer which is designed especially for the dental industry, and it can print almost all kinds of components for clinical use with different kinds of photosensitive polymer resins, such as guides, models, temporaries, wax-up, customized impression trays, etc. The accurate implant guide plate did greatly help the dentist to carry out the implant surgery as their initial plan.

Scan for Digital Single Arch Implant Restoration

In the stage of dental implant restoration, instead of using traditional physical impressions with silicone rubber or alginate, the dentist chose digital impressions by adopting an intraoral scanner to achieve oral data. Digital scan is very helpful to simplify your workflow by optimizing several steps. There is no physical impression-taking, transportation and stone model pouring, waxing, investment, and casting. Fewer processing steps mean less cost of materials and less labour force and time needed for the whole process. What’s more, the digital process will make the workflow much easier to check, analyze, and manage. Compared to paper documents, digital files are easy to record, search, and modify. By the way, there is less space needed to keep all this information while you may need a bigger room to store the stone models. On the other side, the whole treatment is more comfortable for patients since no physical impressions are needed, which may cause patients to have symptoms such as nausea or vomiting. Even the inexperienced user can finish one single full-arch scan in 30 seconds with Aoralscan 3, which is much lower than the 5 minutes required by the traditional impression.

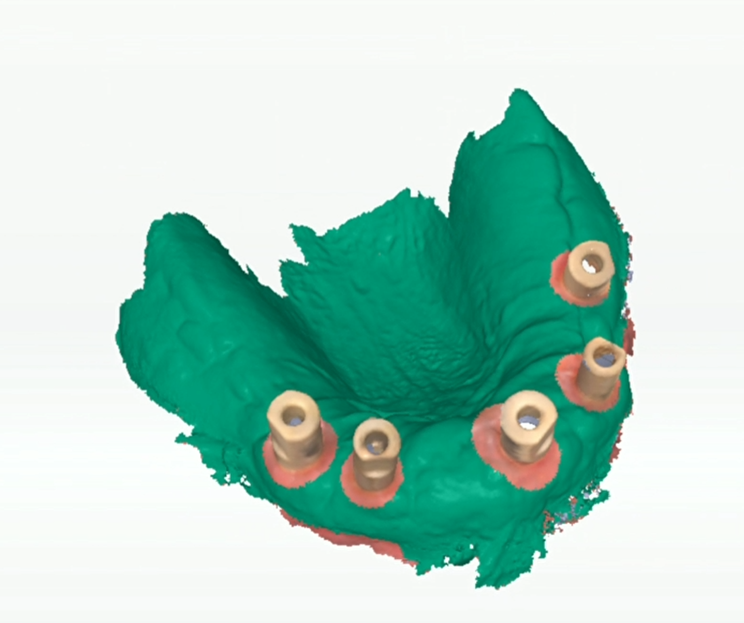

In this case, dentists scanned the upper jaw first. The full denture of the upper jaw made it difficult to scan since there were almost no feature points in the target scanning area. However, placing one scan body at 11 tooth position, increased the feature point of the whole denture, making it easier for our scanner to scan and decrease the risk of distortion of the dental arch. After removing the gingiva data around the implant body, the dentist placed all 5 scan bodies into the patient’s mouth and achieved the oral data again, then moved forward to the lower jaw scan and bite scan.

Design

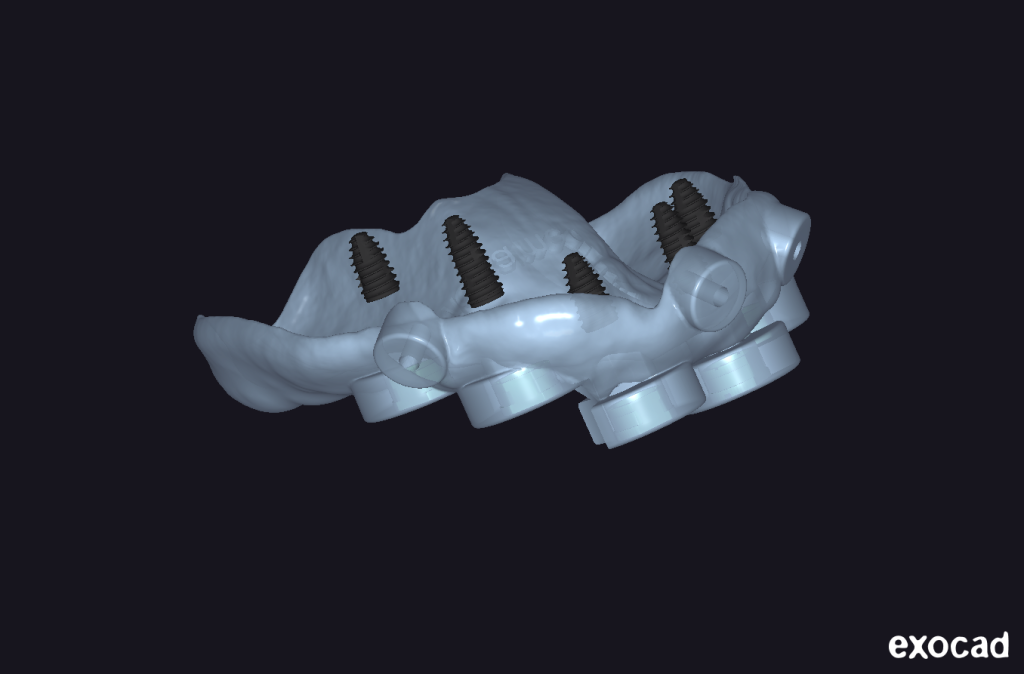

The design of implant restoration is different from that of natural teeth support. To design implant restoration, more attention will be paid to the transmission of force in the occlusal process, occlusal contact morphology, buccolingual diameter, emergence profile design and other factors, which determine the direction and size of the force, as well as the situation of its spread along the implant. What’s more, due to the extensive denture missing from the upper jaw, it is important to pay attention to the interior teeth aesthetic. In today’s case, the #15~#25 long bridge was designed through exocad. What’s more, to spread the occlusal force at the posterior area and make the whole bridge more stable, the designer made 15 and 25 into 16 and 26 maxillofacial morphologies.

Try-on temporary bridge

Try the temporary bridge on the printed model to check whether the occlusion, margin line, proximal contact, and overall morphology of the restoration meet the requirement. If the restoration is not suitable, it can be detected and adjusted. After everything was ready, the temporary bridge was placed on the patient so that the teeth were available while the patient waited for the final restoration.

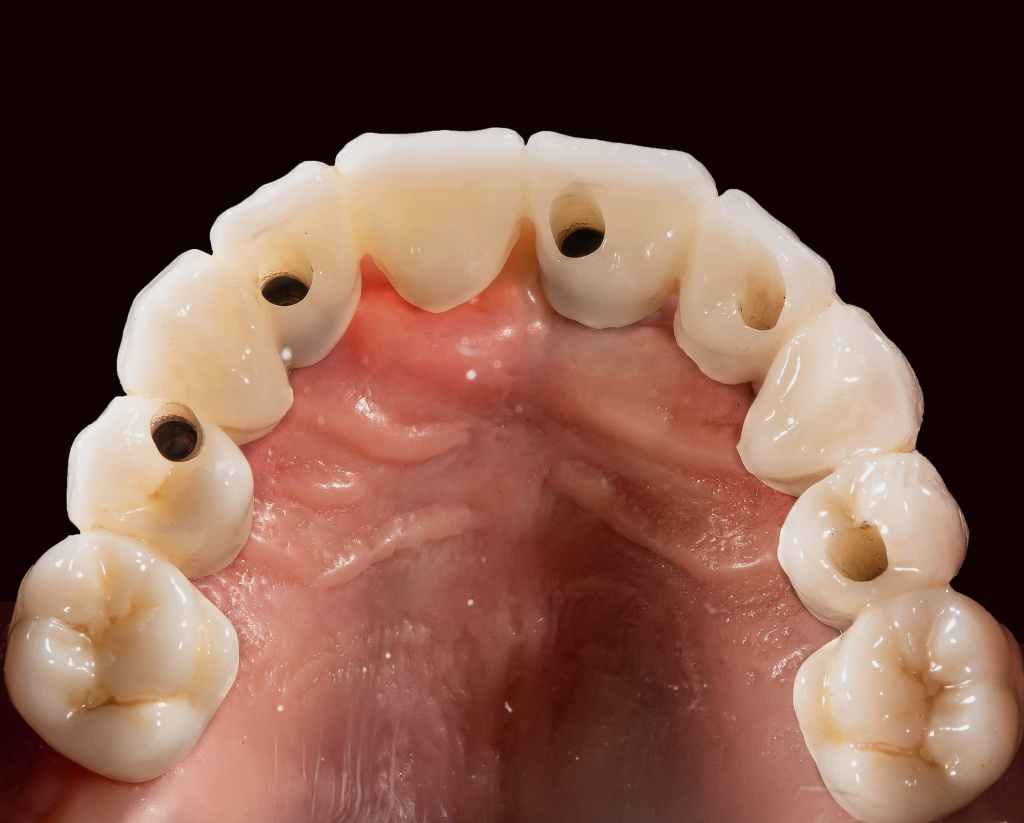

Final restoration

After glazing and porcelain, the final restoration made of zirconia was placed into the patient’s mouth. Through a series of treatments and recovery, the patient finally has new teeth and can eat freely without limitation. This is the great power of digital technology when being used in dentistry, to help dentists and patients get a good result most appropriately. The digital single-arch implant restoration was successfully achieved.

ENG

ENG