Table of Contents

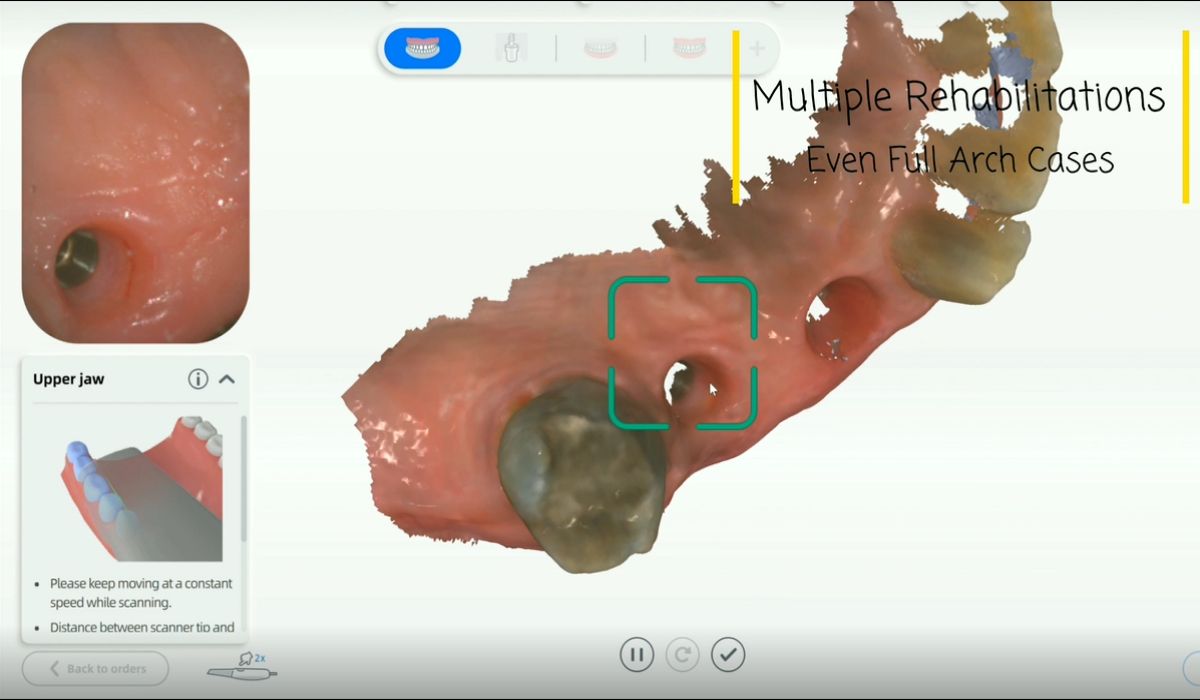

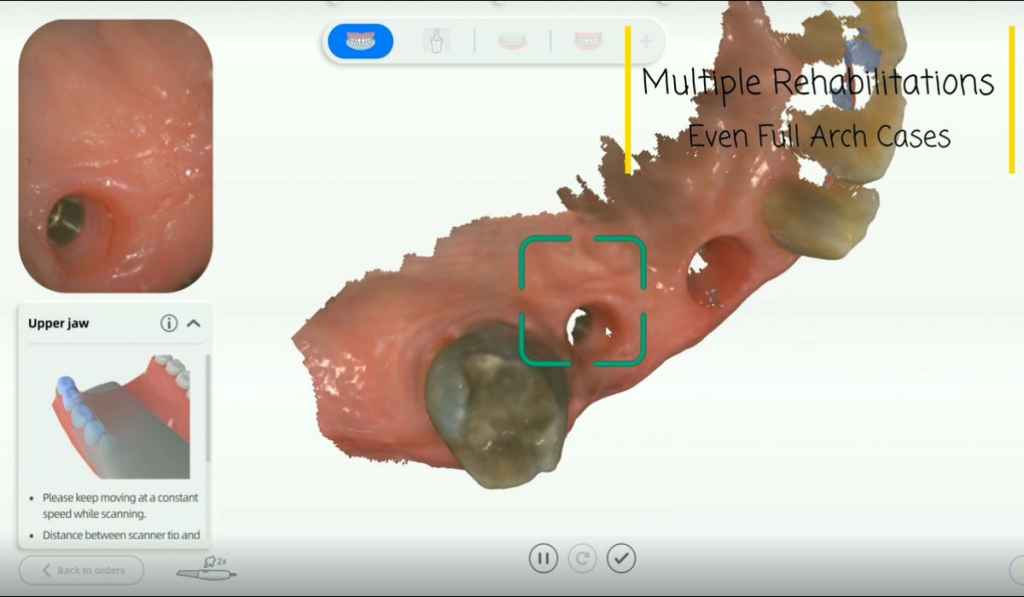

This case explores the use of intraoral scan for multiple implant restoration with the Aoralscan 3 from SHINING 3D.

Introduction

The rapid development and popularization of digital technology in the field of stomatology is changing the way we practice dentistry. Digital impression technology has quickly become the most desired impression technology for dentists and patients alike. The reasons are easy enough to see: digital impression technology offers efficient clinical operation, comfortable patient experience, convenient doctor-patient communication, easy data storage, and more.

Direct and indirect digital impressions

Digital impressions can be divided into two categories: direct, and indirect.

Indirect impressions are scans of plaster models. We typically make them using a desktop scanner such as SHINING 3D’S DS-EX and DS-MIX. This technique is now relatively mature and increasingly popular, what with the wide application of CAD/CAM in the clinical setting.

The direct impression method involves taking scans directly from the implant site. This way, the dentist and patient can completely avoid traditional impressions. A scan of the actual implant’s location generates its digital data and location information. Planning and modelling are then possible with this direct impression data.

Below, we’ll look at a restoration achieved using multiple implants scanned in real-time with the Aoralscan 3 from SHINING 3D.

Intraoral scan for multiple implant restoration: step-by-step guide

- Scan the upper arch with Aoralscan 3, an intraoral scanner from SHINING3D.

- As mentioned previously, this method eliminates the need to prepare traditional impressions. Instead, it digitally creates the impression in real-time. This greatly streamlines the process, removing tasks such as selecting trays, mixing impression materials, impression disinfection, model casting, model transportation, etc.

2. The “true color” feature displays color information to differentiate different parts of the scan. For example, the implant will look different to the teeth or gums. This can allow the dentist to simulate the restoration treatment process so that the patient can intuitively understand the treatment plan and what to expect from the final restoration result. You can send also these scans via Internet to streamline dentist-technician communications.

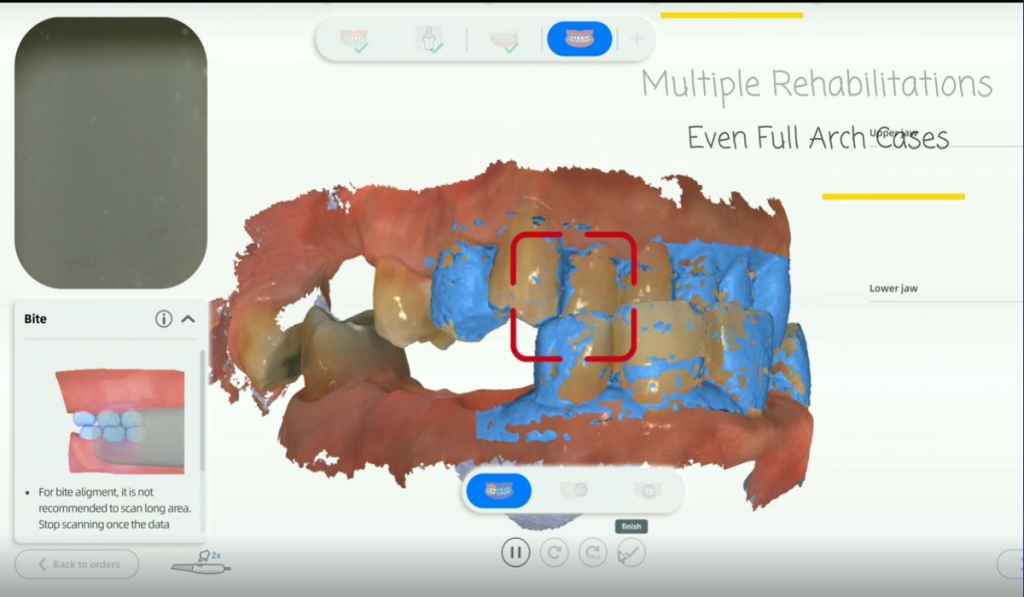

3. Scan the lower arch and measure the patient’s bite. The software aligns the upper and lower arches together automatically. The whole process is smooth for both you and your patient. These digital impressions can be stored on CD, hard disks, and other easily available storage.

Digital impressions not only streamline the process for both patient and dentist, but also cut down on waste. They eliminate the need for physical storage space, and the need to throw out impression materials.

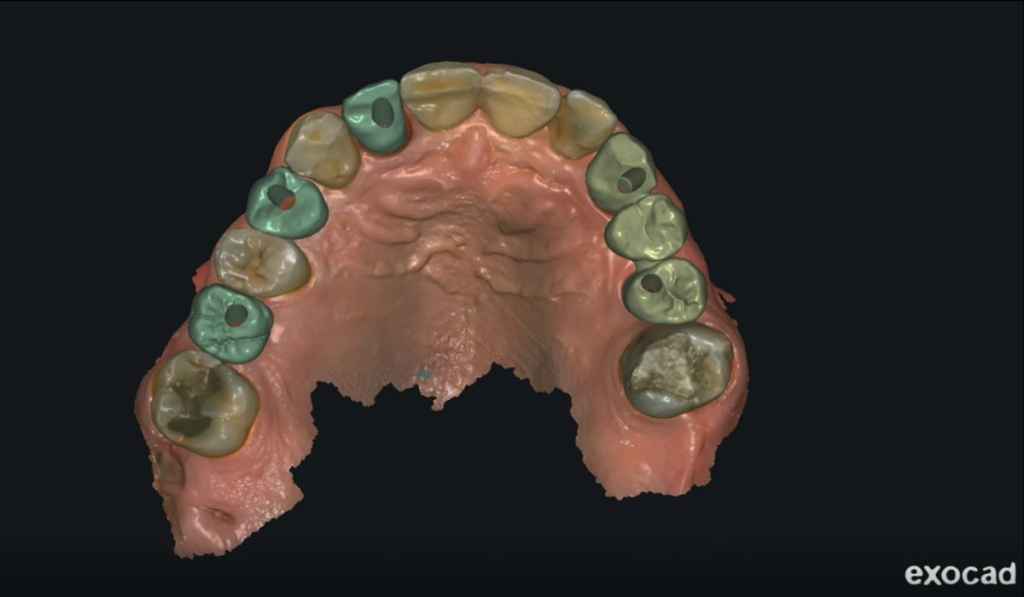

4. We can make the restoration design with exocad. We then mill these STL files to manufacture the restorations.

5. Finally, test the restorations in the patient’s mouth and finish cementing in place. In this example, the patient expressed satisfaction with the speed and comfort of the entire treatment.

ENG

ENG