Table of Contents

This case study explores the use of an intraoral 3D scanner to create a 3D printed surgical guide.

Introduction

A 3D printed surgical guide provides precise positioning for dental surgeons. It avoids the common sidewall perforation in implant surgery, as well as poor position, direction, and depth of the implant. A surgical guide can also help prevent damage to the maxillary sinus, mandibular neural tube and other important anatomical structures.

It can truly simulate the whole process of oral implantation. Indeed, it can accurately navigate, track and detect the central location of implant drilling, and has an early warning function of implant spacing. Minimally invasive surgery is the highlight of the implant guide. Circumferential supracrestal fibrotomy can greatly reduce postoperative complications and patients’ fear of surgery.

Patient information

This is a 54-year-old male patient with a fixed orthodontic appliance and anchorage nail in the mouth. Teeth #15, #25, #36, and #45 were missing. In order to reduce the trauma, we will utilize the Aoralscan 3 to acquire the jaw data. We’ll then design our surgical guide based on this data and 3D print the guide with the AccuFab-D1s. Finally, we will accurately place 3 implants in area #25, #36 and #45 under the guidance of the surgical guide. The aim is to reduce postoperative complications and reduce the fear of patient.

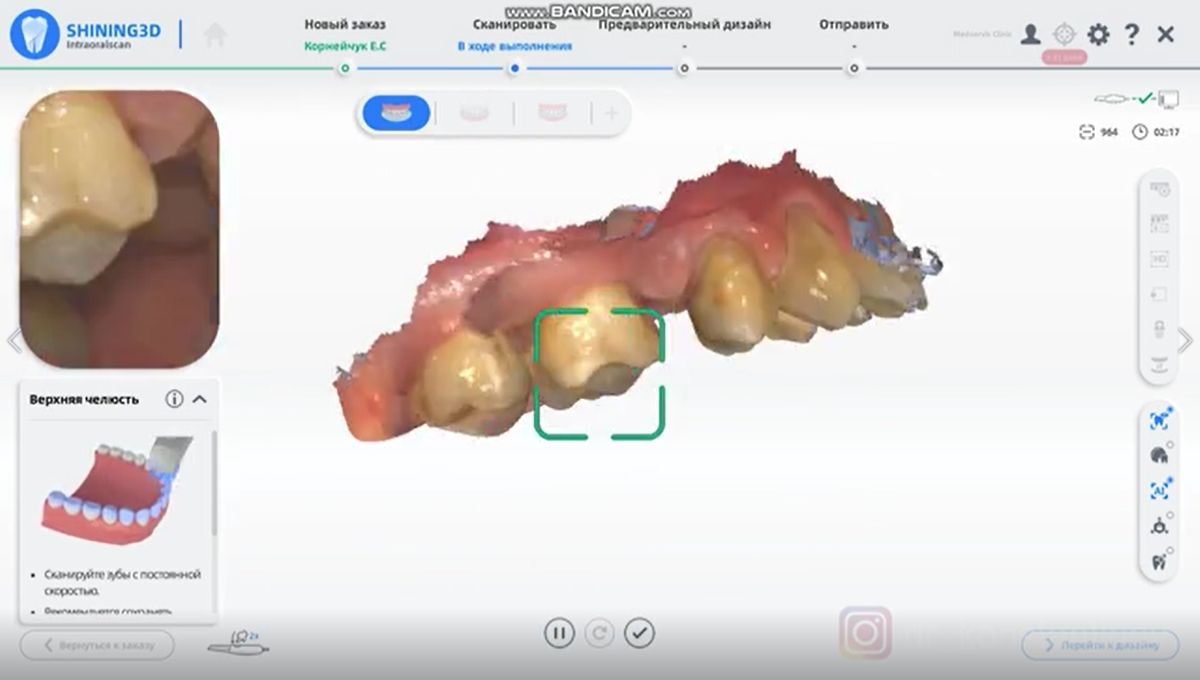

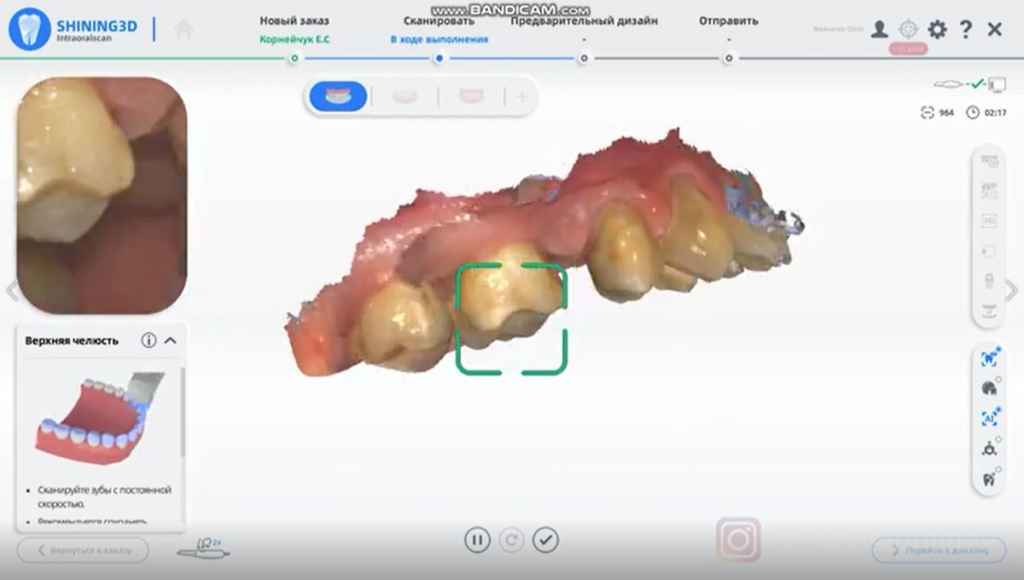

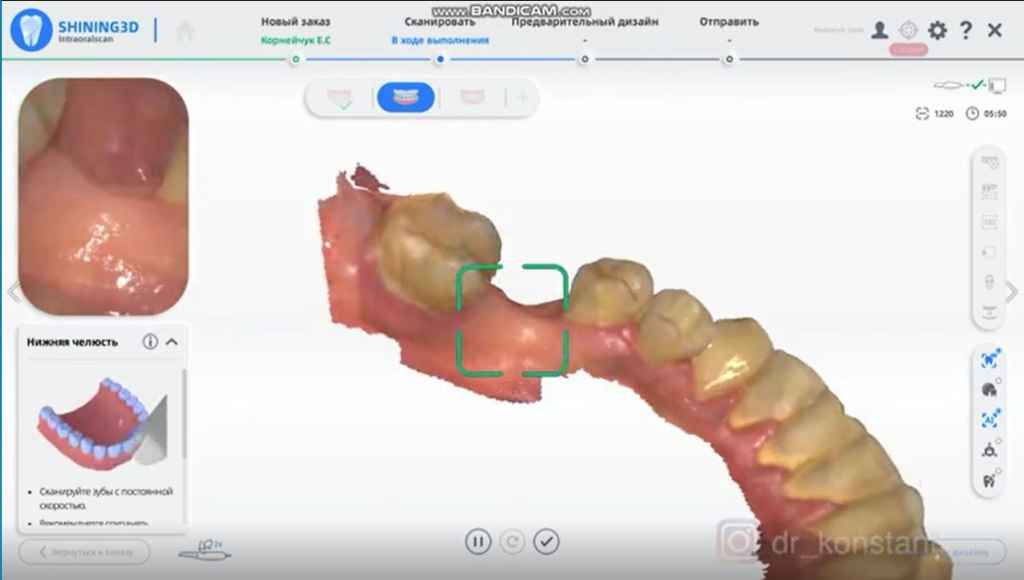

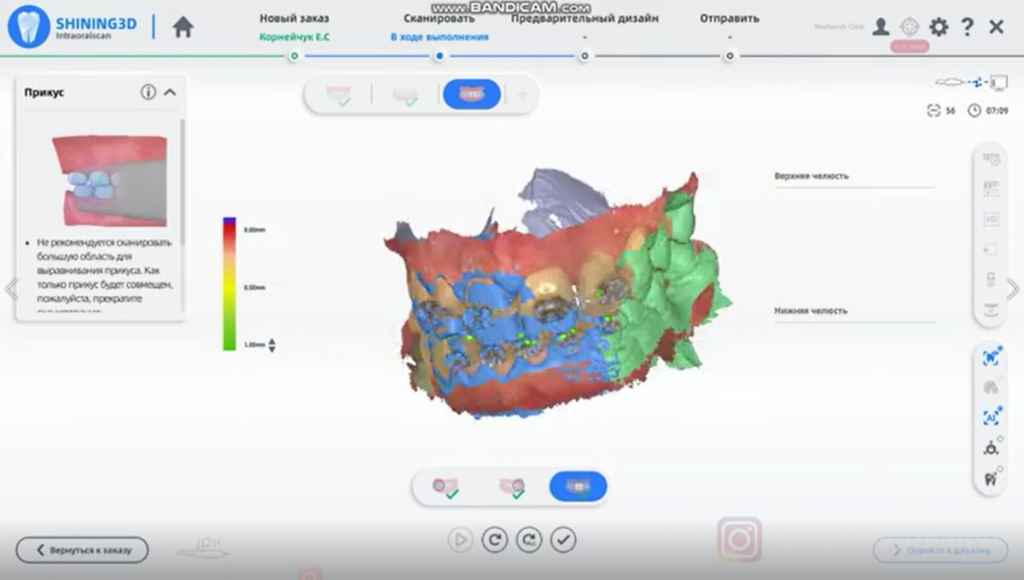

3D scanning and 3D printing

With Aoralscan 3, we can get the jaw data with true color. Compared with the traditional impression process, the digital one is very convenient and fast for doctors, and the patient experiences no unpleasant feeling.

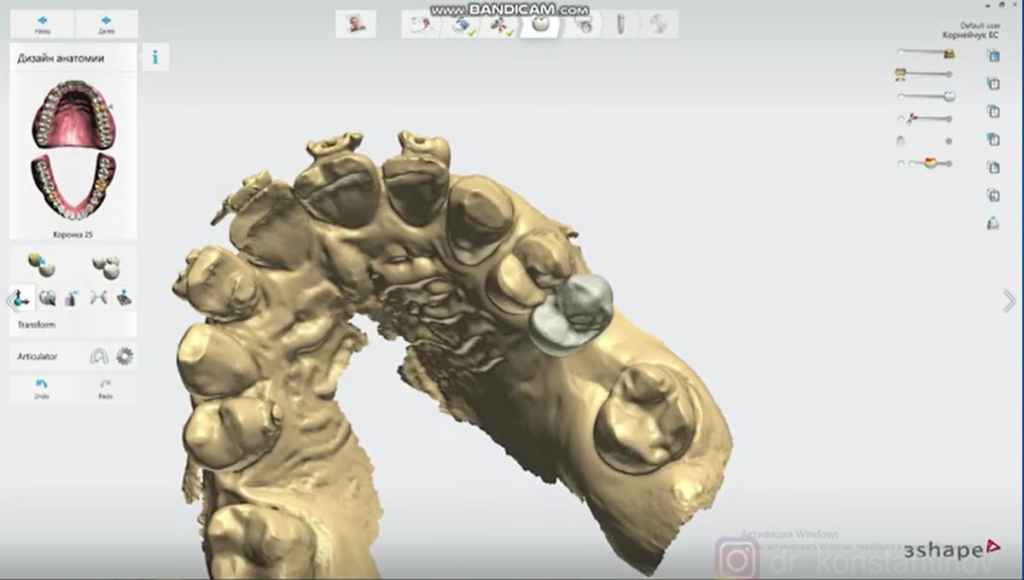

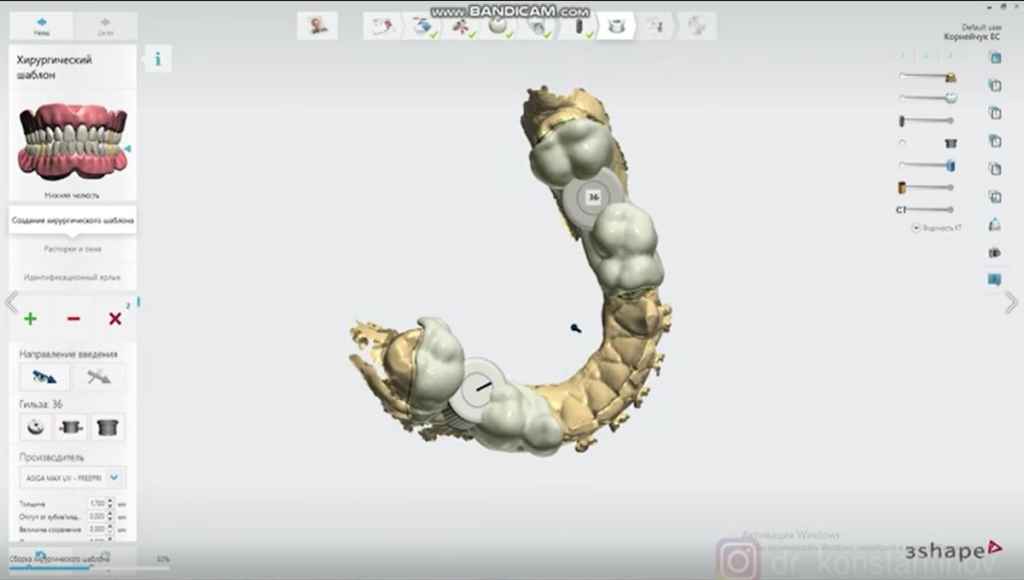

Based on the digital impression, we can first set the teeth arrangement. Then we place the implants according to the position of the teeth, to determine the specific direction and depth of the implant.

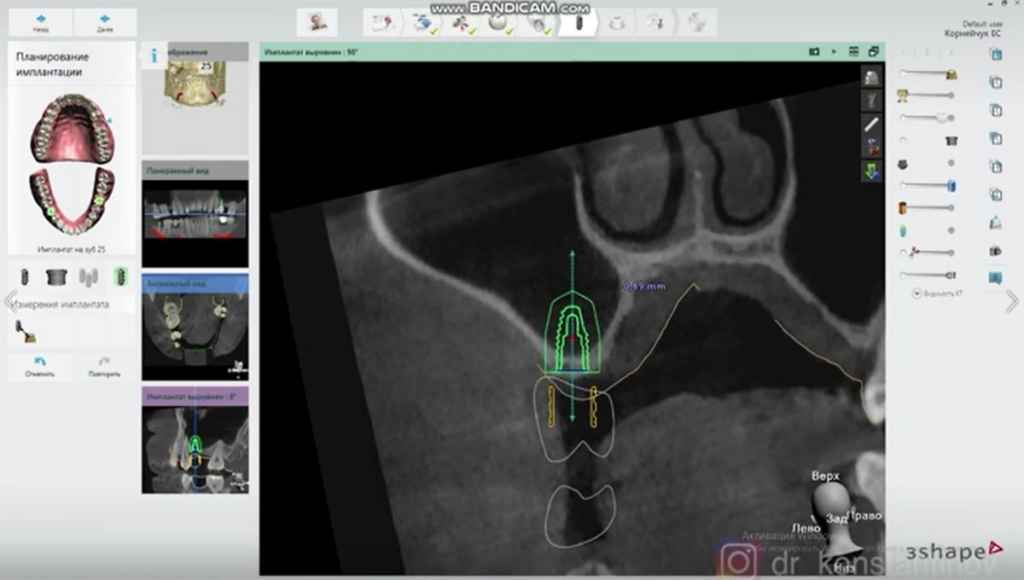

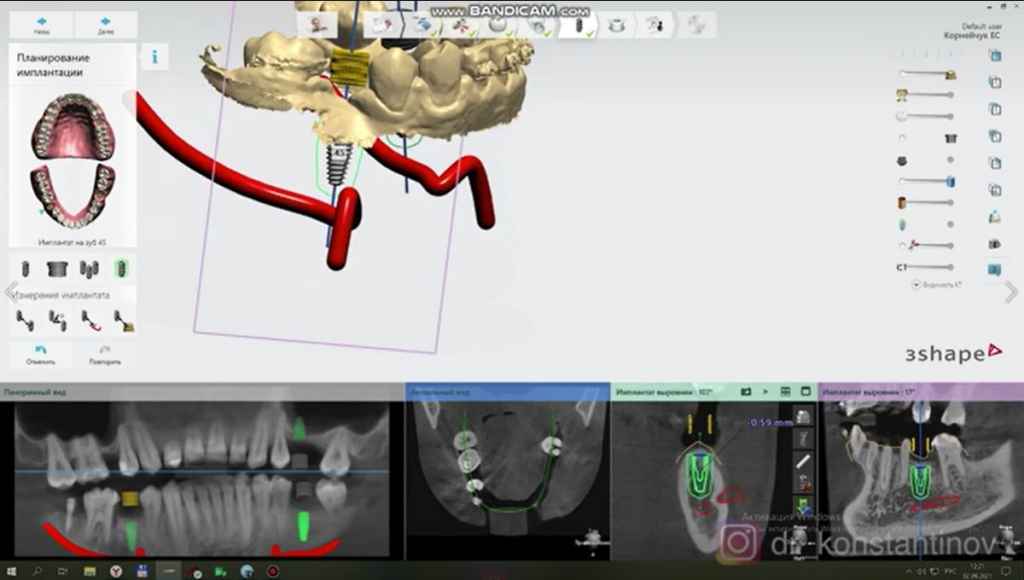

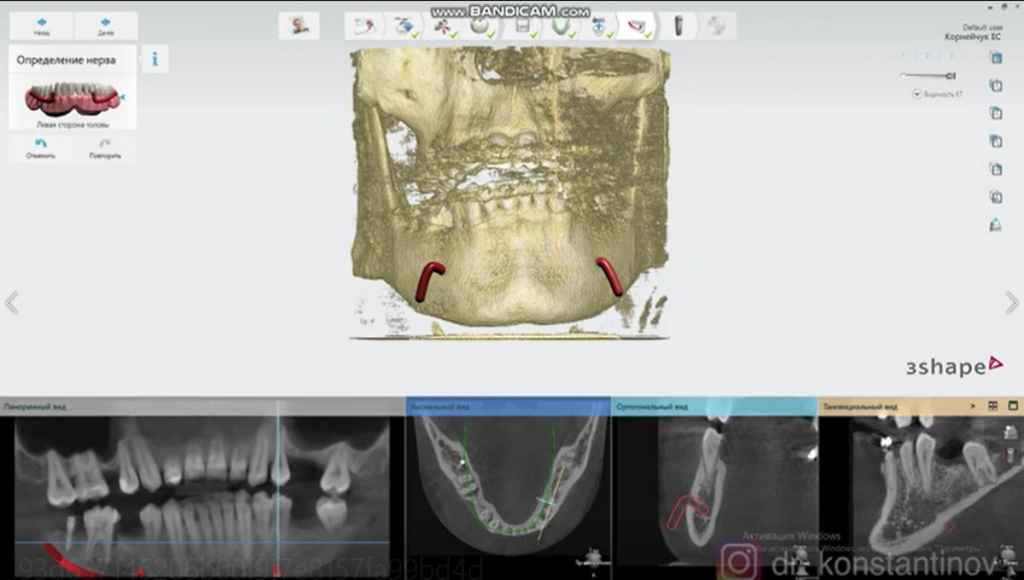

To create neural tube in the software, since the CT data is intuitive, we can select the size of the implant accordingly to avoid damage to the neural tube. At the same time, we can know whether the maxillary sinus needs to be lifted and the height needed to be lifted.

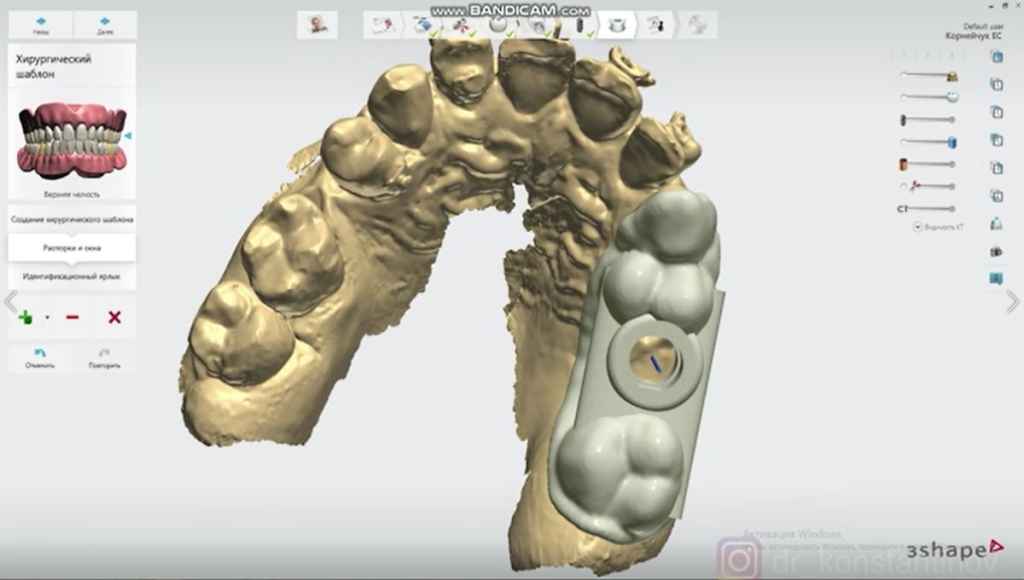

Finally, after the implant planning is complete, the surgical guide can be generated, and all the planning information can be output in the form of a guide.

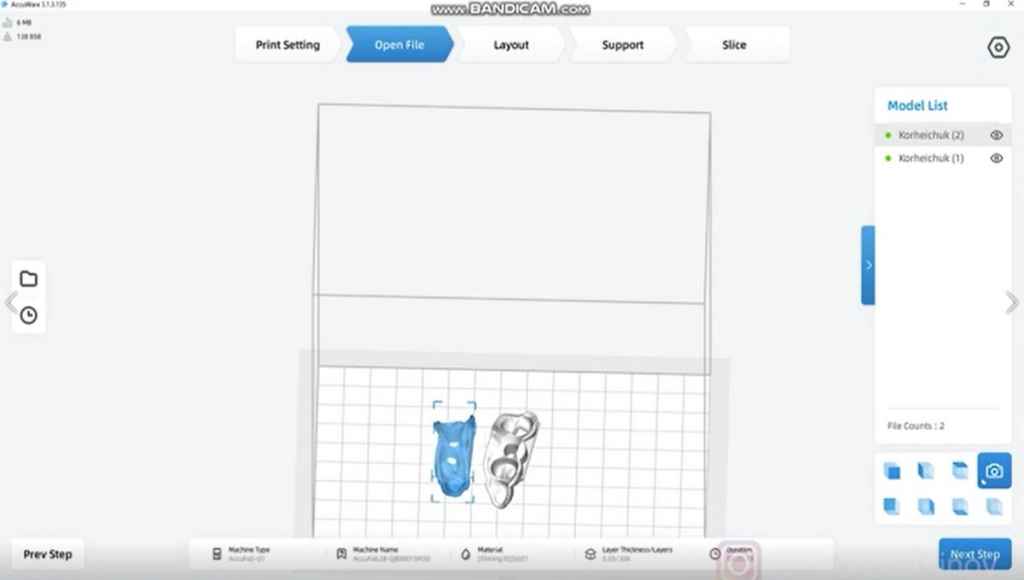

Then, we can utilize AccuFab-D1s to print the designed surgical guide.

Conclusion

With a 3D printed surgical guide, doctors only can easily and accurately place the corresponding implants according to the corresponding planning information. This method is minimally invasive, safe, accurate, and efficient.

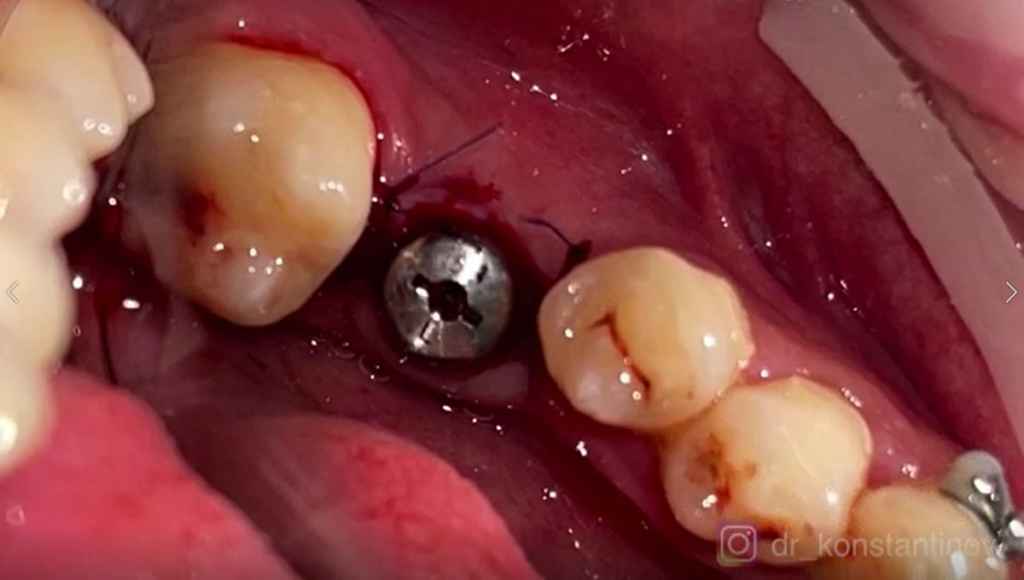

This is the post-op image. We can see that with the guidance, the implants were in place exactly as planned.

ENG

ENG