Orthodontics focuses on addressing the diagnosis, prevention, management, and correction of mal-positioned teeth and jaws, as well as misaligned bite patterns. It usually takes one or two years for the whole process. However, there is still lots of work need to be done after the braces are removed. Retention is a critical follow-up stage that usually involves wearing a customized orthodontic appliance, called a retainer. In this article, we will discuss how digital technology can help to make customized retainers for post-orthodontic treatment.

Case Profile

The patient in this case is a 15-year-old female who presented with mild third skeletal class with upper and lower tooth crowding at the beginning of the treatment. The whole process lasted for around 20 months employing traditional metal brackets.

Fig 1,2,3: the intraoral condition before orthodontics treatment & Fig 4,5,6: the intraoral condition after orthodontics treatment.

Treatment Process

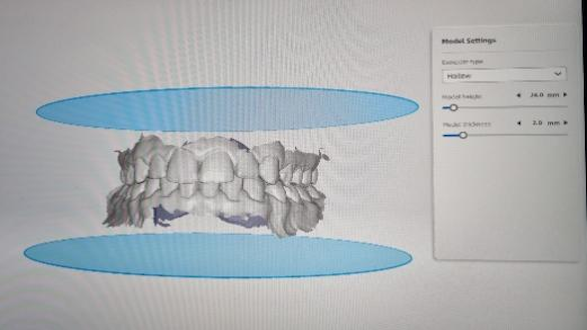

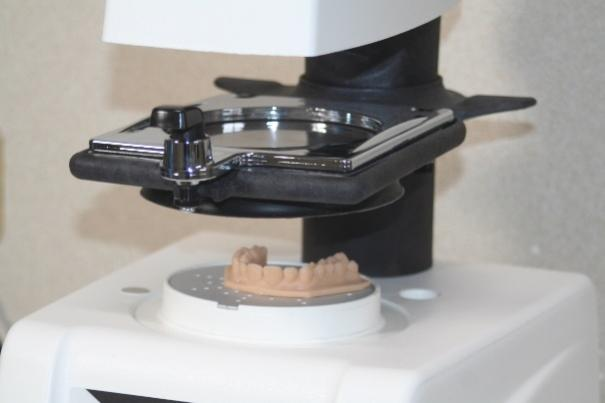

After removing the metal brackets, the dentist used the Aoralscan 3 scanner to capture digital impressions of the patient’s arches. The Aoralscan 3 is an elegant scanner that provides a comfortable experience for the patient during the data capturing process. It is fast and accurate. Then scanned data was imported into Accuware for slicing and printed using the AccuFab-D1s 3D printer. The AccuFab-D1s offers a more intuitive and user-friendly workflow with faster print speed and better accuracy. After post-processing with the Fabcure curing machine, the model was used to create a retainer. Using a thermoforming machine, the dentist made the retainer mask using the 3D printed model and placed it into the patient’s mouth. The whole process took about an hour and a half to complete, thanks to these advanced digital technologies that made the entire process seamless and highly efficient.

Fig 7,8: Intraoral scan process with Aoralscan 3.

Fig 9,10: Modeling by AccuDesign

Fig 11: The AccuFab-D1s printer, FabCure light curing box and the printed model

Fig 12: The process of making the retainer. & Fig 13:The retainer and its model.

Comments from Dentist

According to Dr. Andrea Carlo Butti from Milan University, the digital products used in this process, including intraoral scans, and slicing software and 3D printers offer a one-stop solution that greatly improves the patient’s case while increasing the treatment’s effectiveness. The technology is fast, accurate, and easy to use, which makes it an ideal solution for creating customized retainers.

About the Author

Monday Morning Orthodontic Team consists of orthodontic specialists, residents and also dentists and dental students. It is the group that deals with orthodontic therapies in the context of the Oral Rehabilitation Department of the University of Milan located at the Italian Stomatologic Institute.

ENG

ENG