Digital technology used in dental treatment could make the whole process more accurate, more comfortable, and more cost-effective. In a recent case, Dr. Luis Estuardo Pacheco from Guatemala utilized the Aoralscan 3 intraoral scanner to capture a digital impression for the replacement of two crowns, subsequently utilizing 3D printing to fabricate temporary teeth. This innovative approach enabled the delivery of same-day temporary restorations.

Case Profile

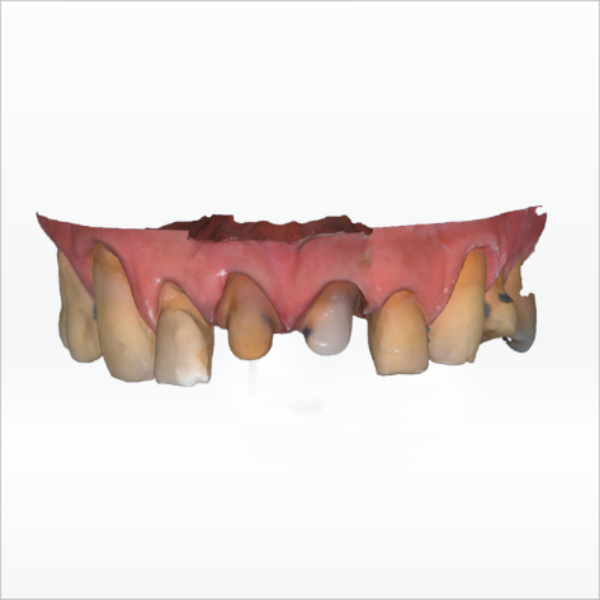

A 55-year-old patient presented with a longstanding missing tooth (#21) and an aged restoration on tooth #11 with gingival degeneration. Seeking esthetic improvement, the patient requested the replacement of two crowns in the anterior region.

Treatment Plan

The treatment planinvolved the removal of the old restoration on tooth #11, and have it repaired together with #21, using zirconia crowns.

Treatment process

Teeth preparation

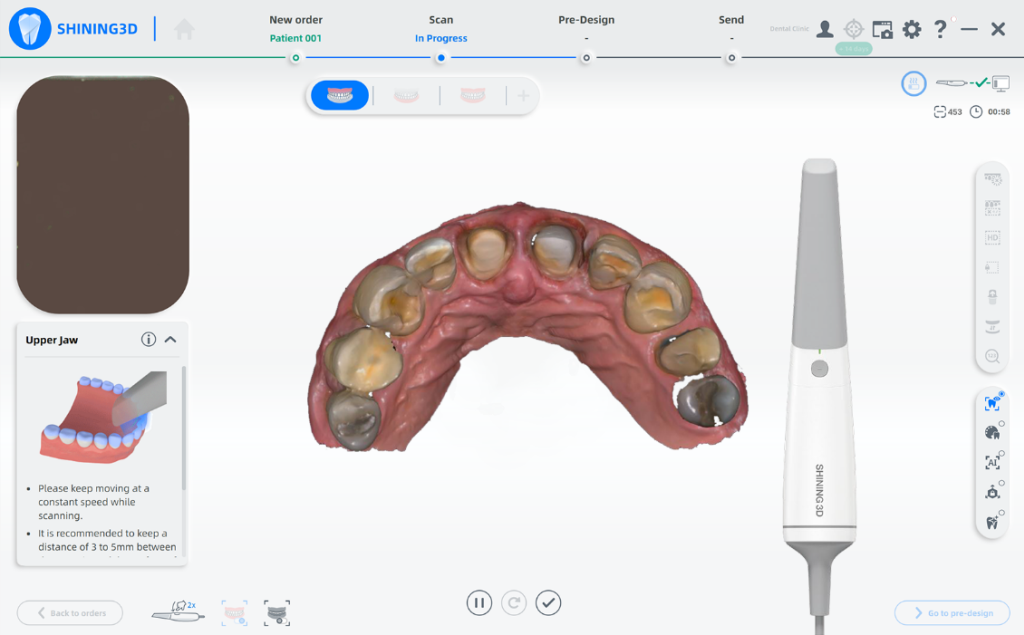

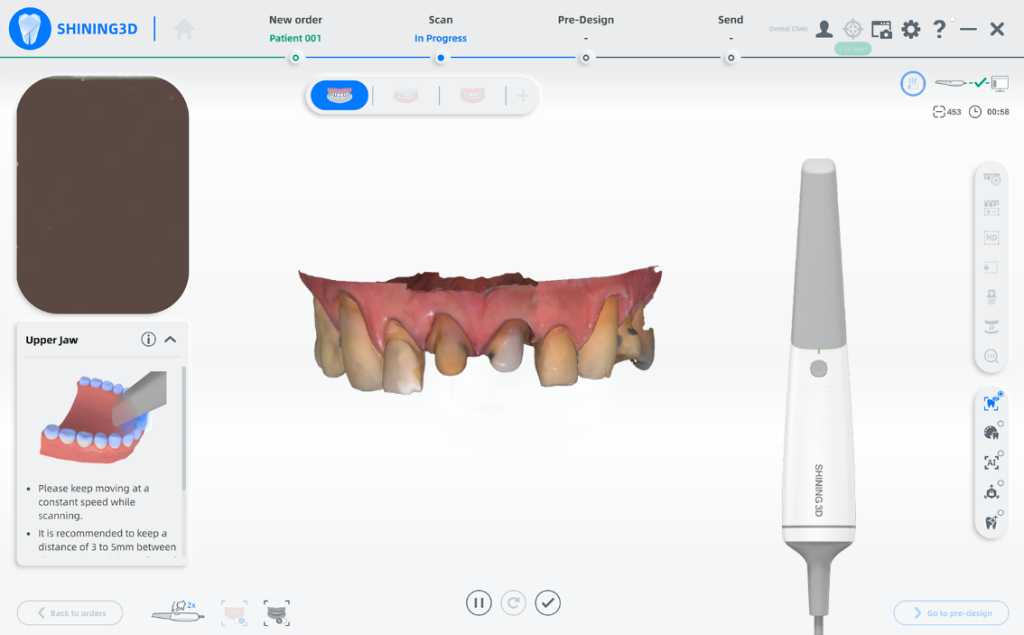

Following teeth preparation, Dr. Pacheco utilized the Aoralscan 3 intraoral scanner to obtain digital impressions, eliminating the need for physical impressions. This digital alternative offered increased convenience, especially for patients who are sensitive and prone to discomfort or gag reflex during traditional impression-taking.

Temporary crown design and print

Utilizing the intraoral scan data, Dr. Pacheco designed two temporary crowns using exocad software in real-time chairside. These designs were then promptly 3D printed using the AccuFab-L4K printer and TN11 temporary restoration material, requiring only half an hour. The temporary crowns were immediately placed in the patient’s mouth, allowing for assessment of occlusion, morphology, and aesthetics. This technique proved highly beneficial in delivering accurate temporary crowns chairside.

Final restorations delivery

After one month, the patient provided feedback on the temporary restorations, expressing satisfaction and readiness for the creation of the final restorations based on the temporary crowns. Minimal adjustments were made to the exocad design, and the STL files were sent to a dental lab for the fabrication of the final restorations using zirconia. A quality inspection model, printed with resin DM12, was employed to ensure the restorations’ integrity before the final appointment with the patient. Any necessary adjustments were made at this stage to optimize occlusion, fitness, and aesthetics.

After everything is ready, the dentist placed the restorations to the patients. With a professional and standard cement process, the final restorations made by zirconia were fixed properly into the patient’s mouth without any adjustment. The patient expressed high satisfaction with the treatment outcome.

Comments from dentist

The use of digital technology allowed for the creation of a temporary crown with precise morphology, providing the patient with an adaptation period for evaluation. In the event of any discomfort, adjustments could be made before fabricating the final restorations. Once the patient approved the temporary crown, an exact replica could be produced using zirconia, streamlining the fixation process with minimal adjustments and ensuring long-term stability of the final restorations.

About the Author

- Dr. Luis Estuardo Pacheco

- DDS., MSc.

- CEO at Dental Studio, Guatemala.

- Senior CAD/CAM consultant, Scientific Team Lab (STL), 3D Labs CAD/CAM Laboratories, Guatemala.

- Senior consultant in oral and maxillofacial radiology at 3D Xray, Guatemala.

ENG

ENG