Table of Contents

Full mouth occlusion reconstruction cases pose significant challenges in dental clinics. In the past, final restorations were often unsuitable and required rework, resulting in wasted time and suboptimal treatment outcomes. However, with advanced digital technology such as intraoral scanners, printers, and dental software, the entire process has become more efficient and accurate. Today’s case comes from Dr. Abdelrahman Khalaf and Dr. Kirollos Hany of the Faculty of Dentistry at Assiut University (Fig 1).

Case Profile

Missing teeth in both the upper and lower arches have resulted in masticatory and esthetic issues that have plagued the patient for years. She has now sought treatment to address these issues.

Treatment plan

Two treatment options were presented to the patient: a removable complete denture or an implant-supported fixed prosthesis. After thorough discussion of the advantages and disadvantages of each option, as well as consideration of financial factors, the patient opted for implants with a fixed prosthesis. The proposed treatment plan involved all-on-six implantation in the upper jaw and all-on-five implantation in the lower jaw, utilizing an implant surgery guide. The Aoralscan 3 Intraoral scanner was employed to capture precise details for occlusion reconstruction.

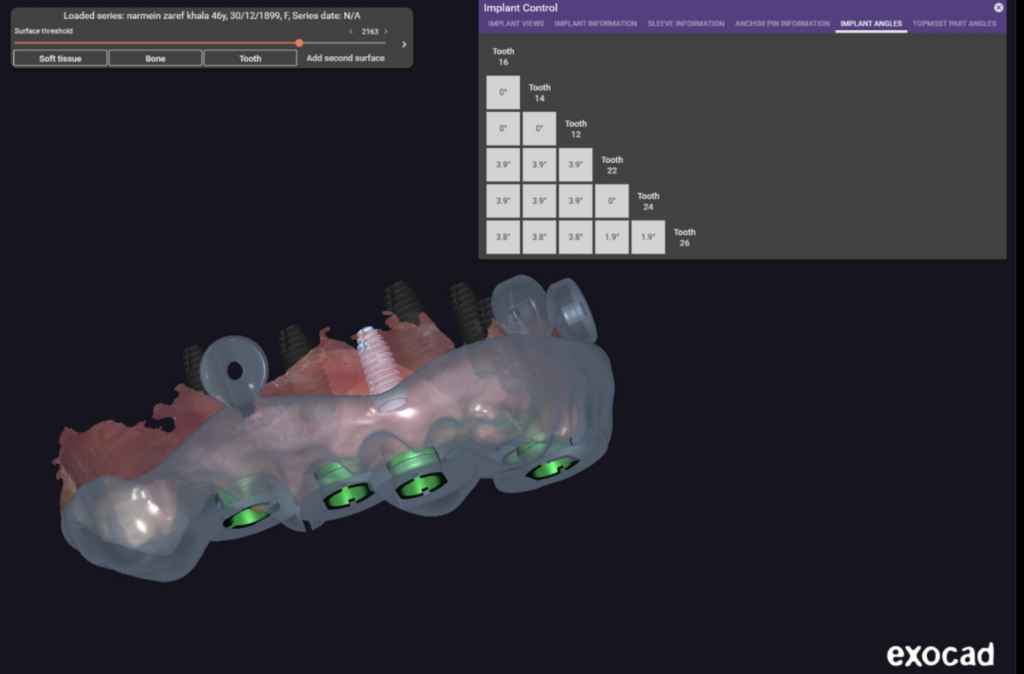

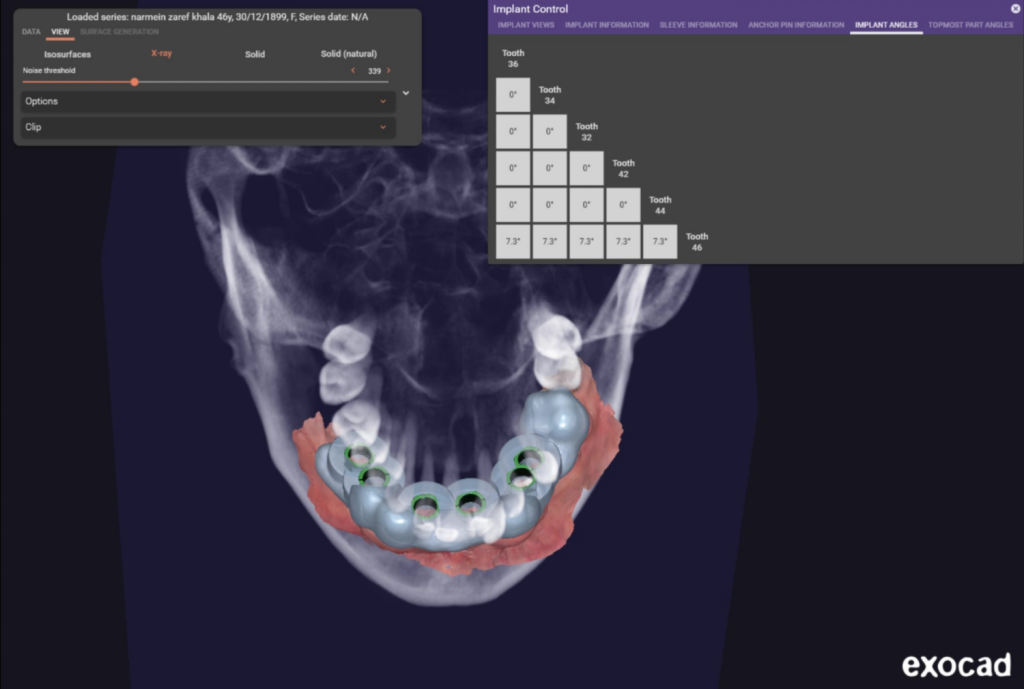

Design and make surgical guide

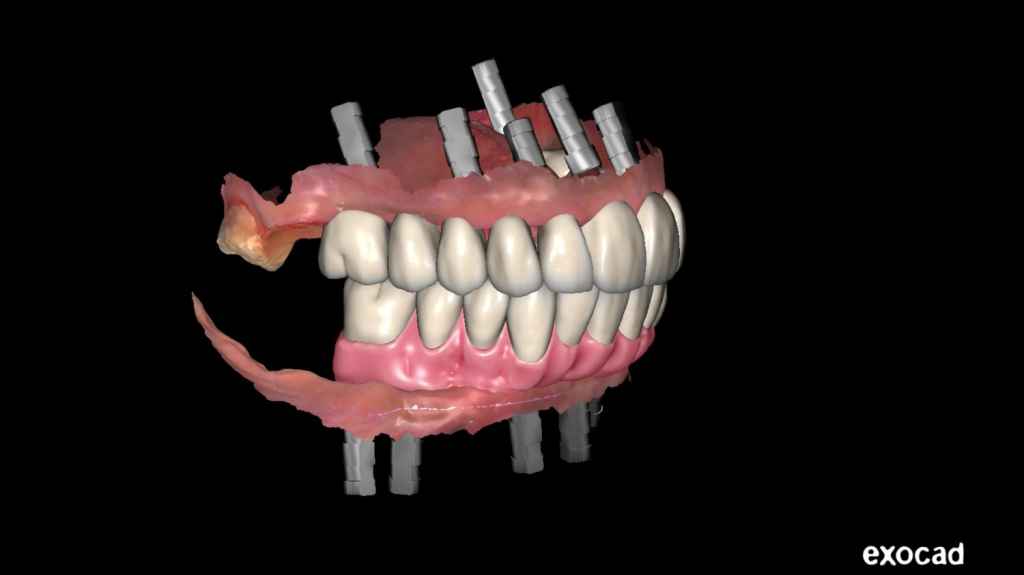

The intraoral scan data was imported into exocad. Two implantation surgical guides were then designed (Fig 2, Fig 3). Once completed, AccuFab-D1s printed the two surgical guides using resin SG01 produced by SHINING 3D. This printer is highly stable and capable of producing various dental products with exceptional speed and accuracy (Fig 4).

The implant surgery and upper restorations

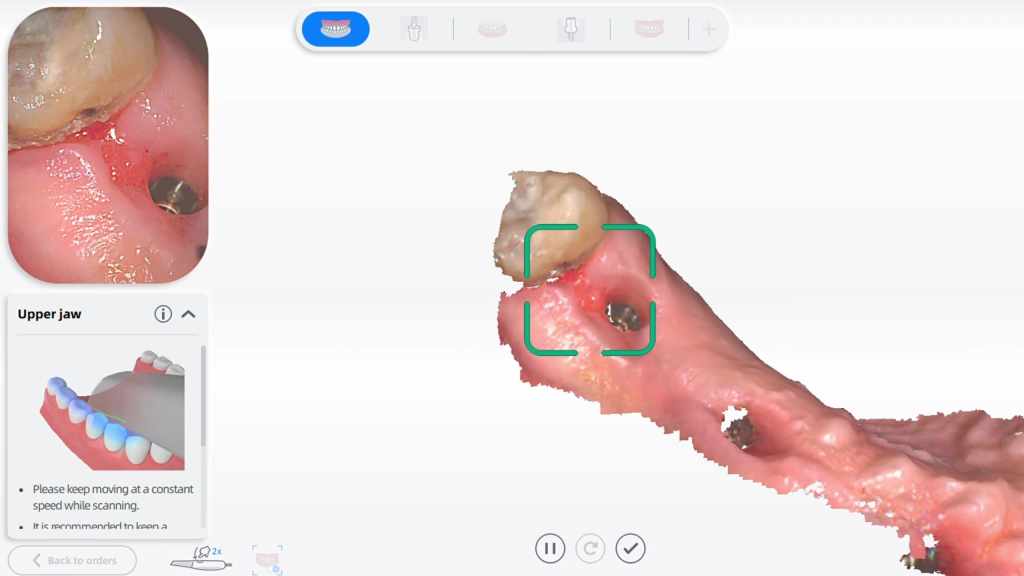

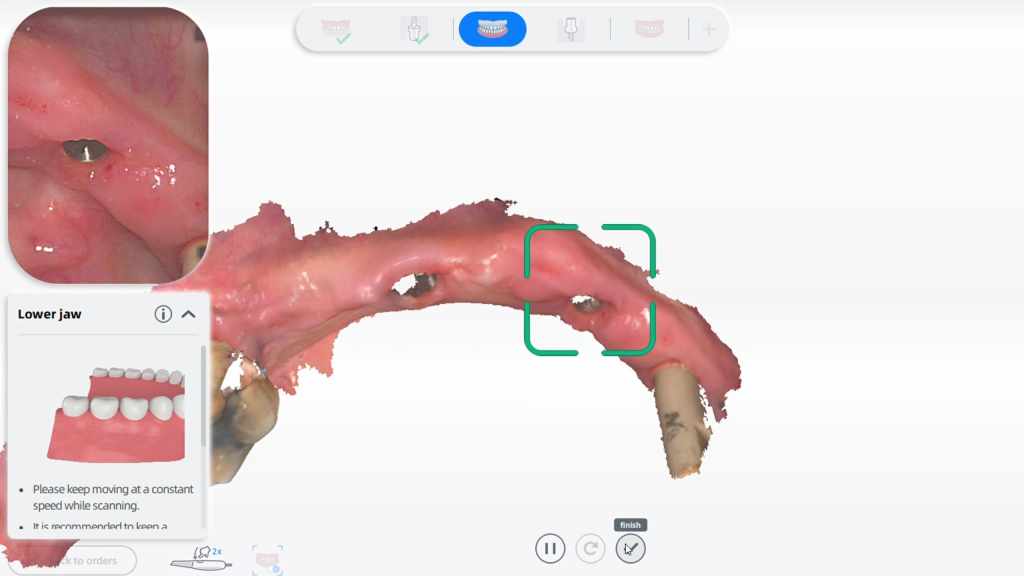

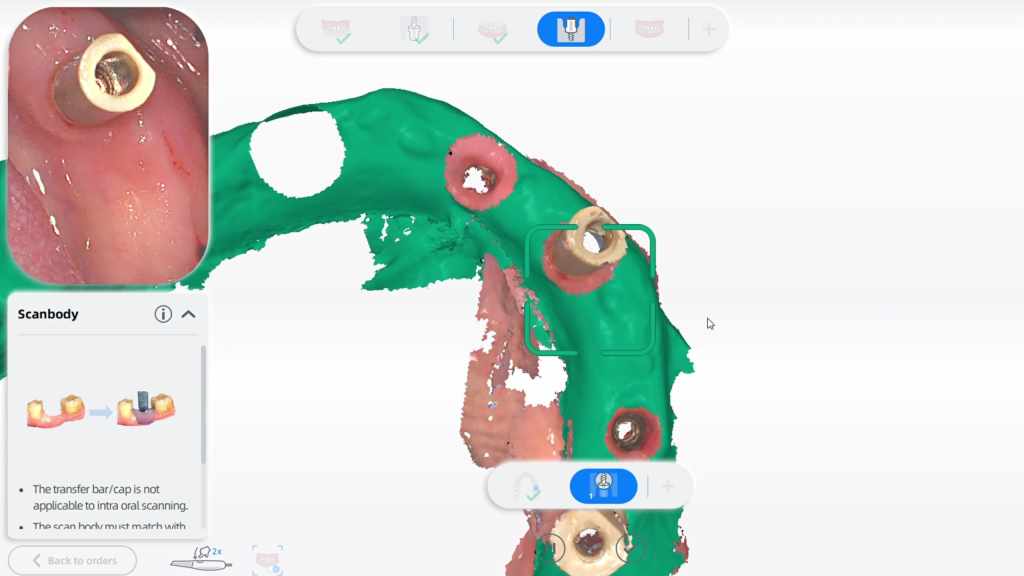

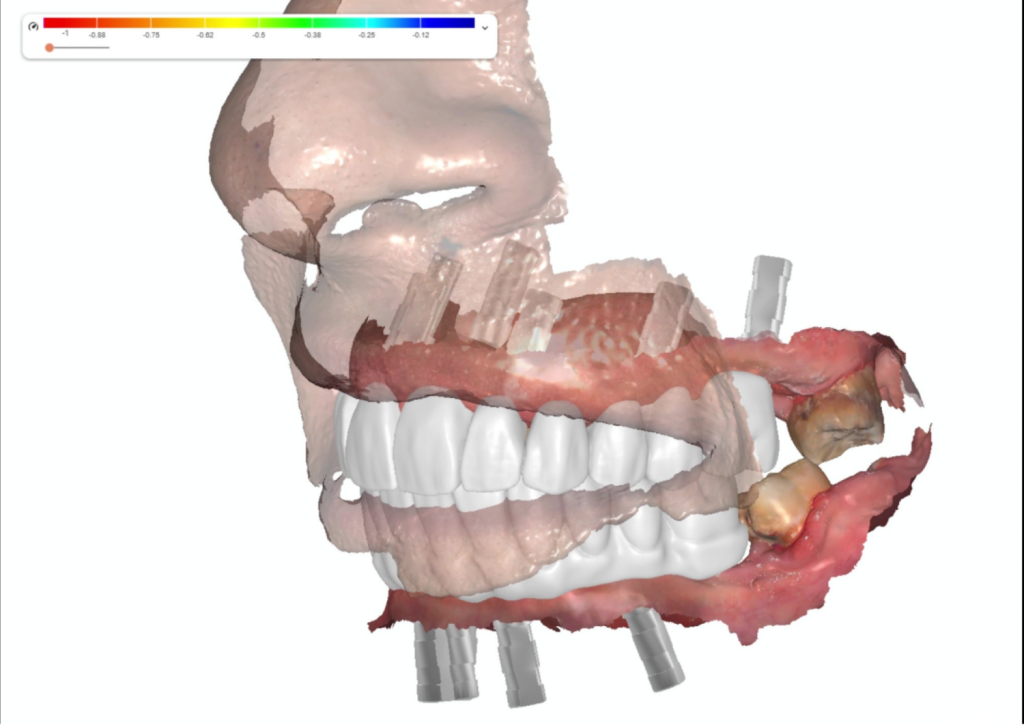

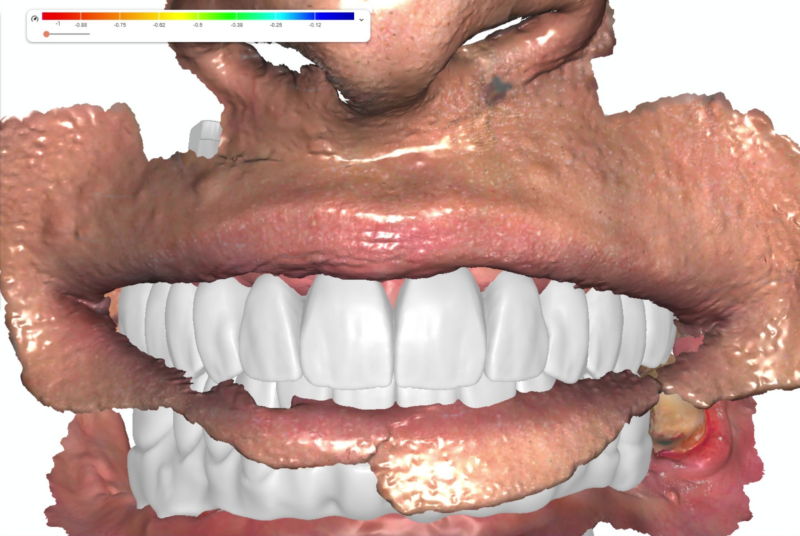

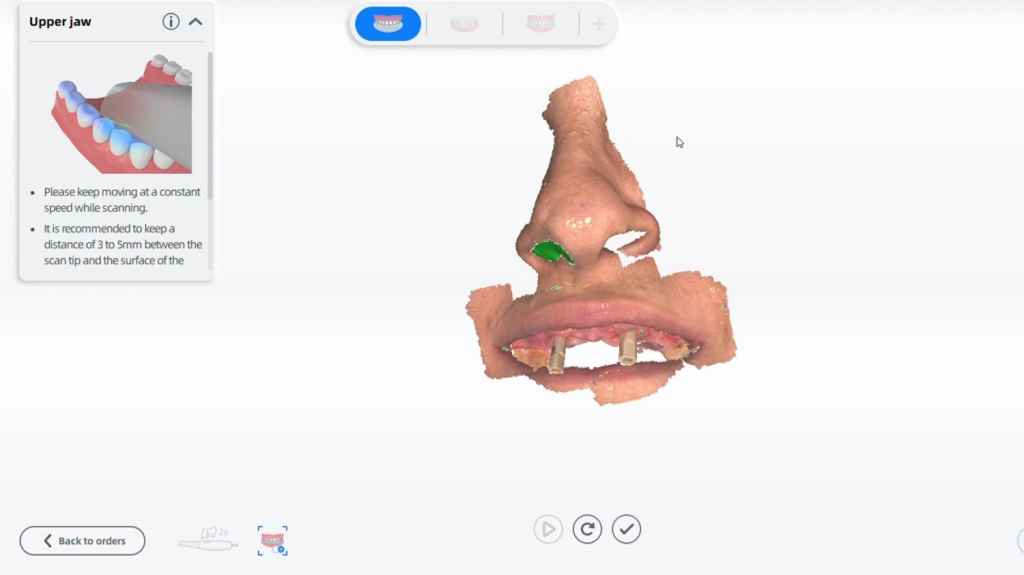

After the implant surgery and a few months of wound recovery, the patient returned for upper restorations. The dentist utilized Aoralscan 3 (Fig 5, Fig 6, Fig 7, Fig 8) to capture intraoral data. This highly intelligent scanner automatically removes unnecessary soft tissues. Additionally, the dentist scanned extraoral teeth and nasal part for alignment and review during later design processes (Fig 9)

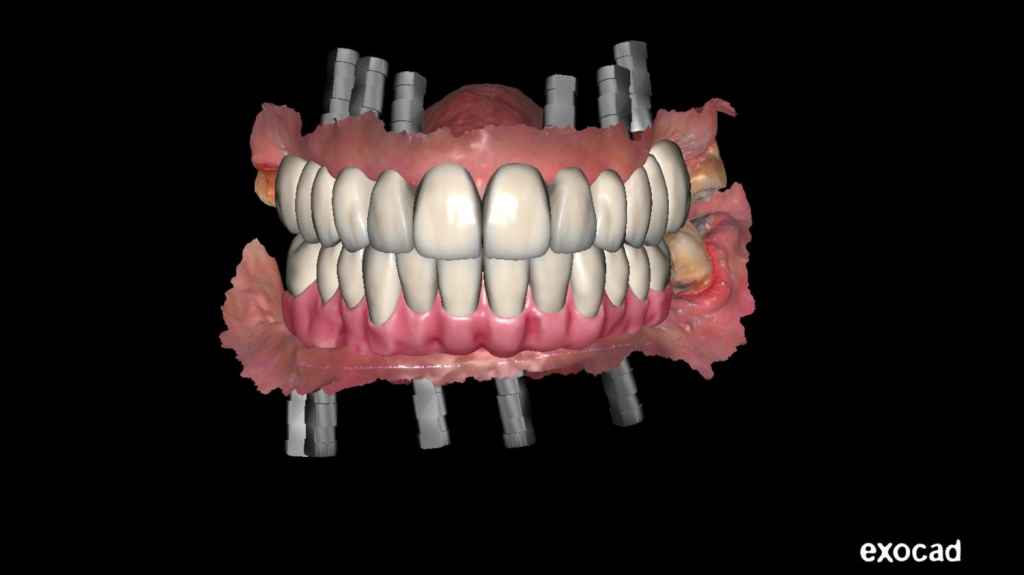

Design in exocad

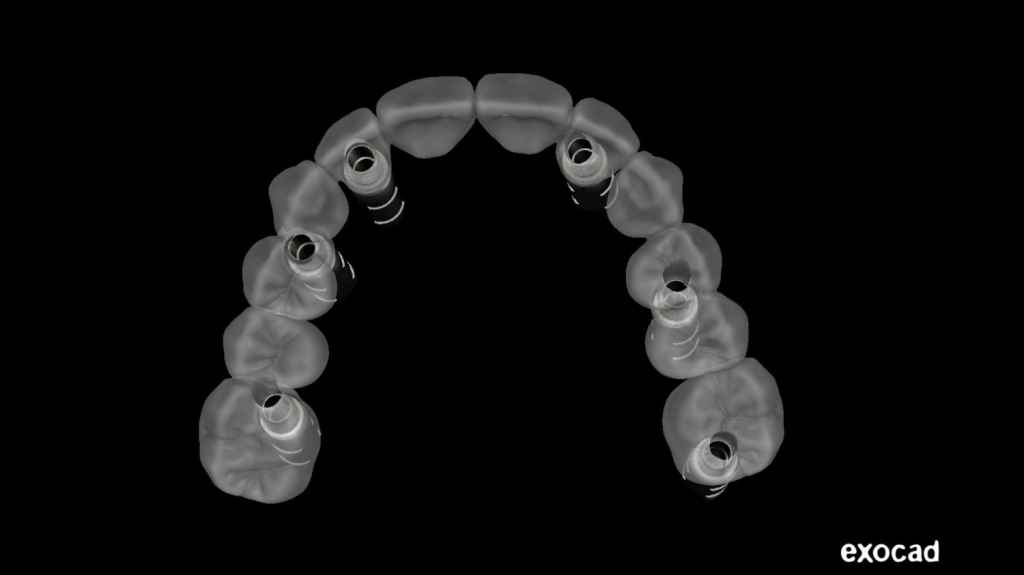

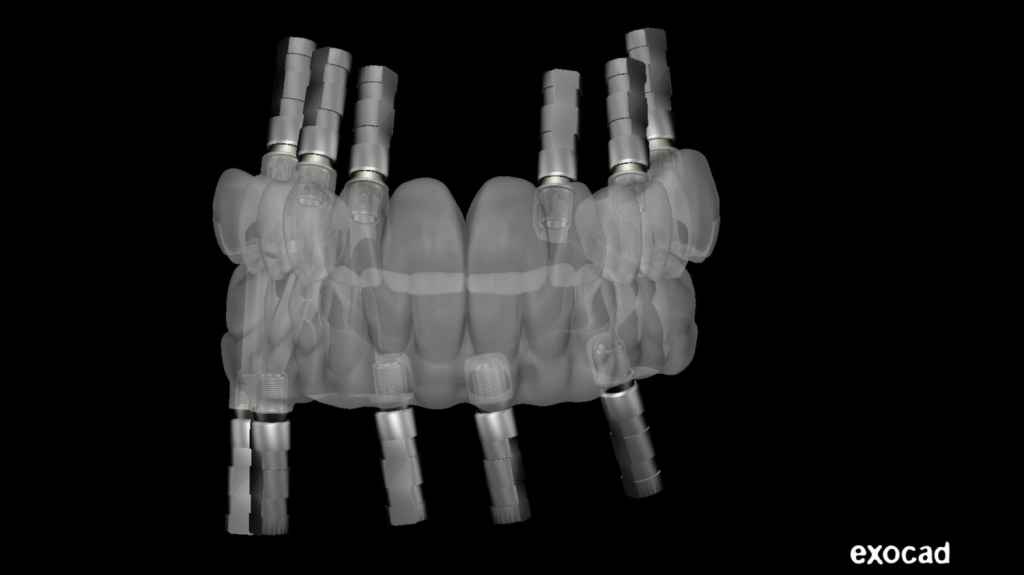

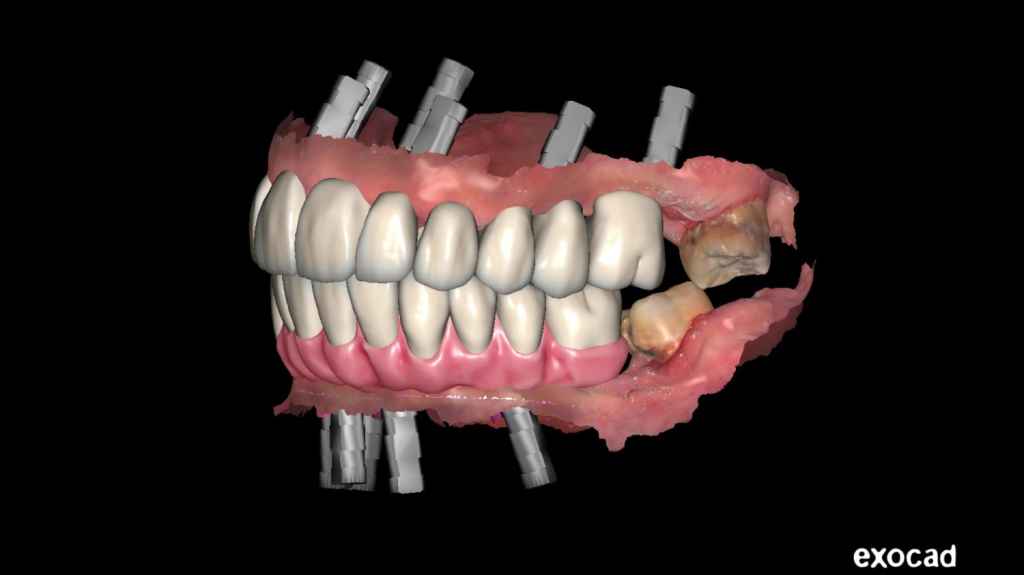

The dental restorations were meticulously designed using professional software, exocad. A total of 24 teeth were restored in both the upper and lower jaws, as depicted in Figures 10-16.

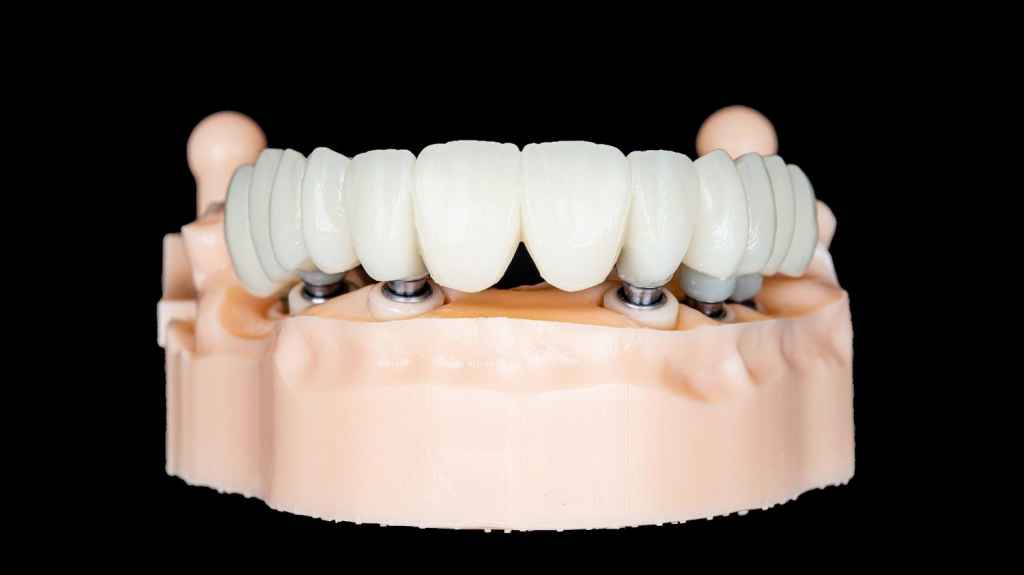

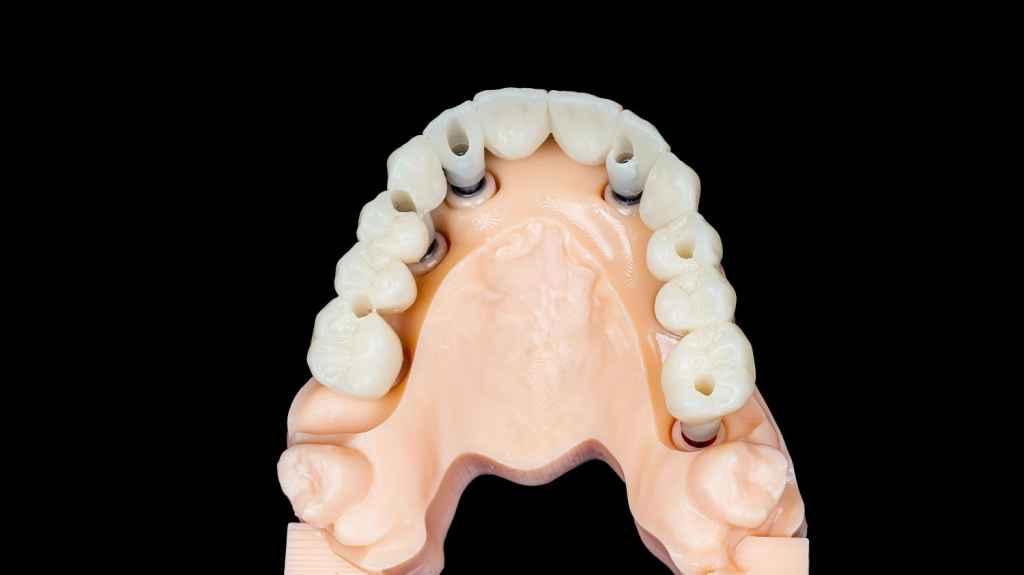

Model try-in and final delivery

Two models were printed for inspection, and the restorations were milled and made by zirconia. During the try-in process, dentists had an opportunity to make any necessary adjustments to the restorations on the model prior to patient arrival (Fig 17, Fig 18). Once everything was prepared, the dentist can seamlessly fix the restorations into the place within the patient’s mouth without significant modification (Fig 19).

Comments from Dr. Abdelrahman Khalaf and Dr. Kirollos Hany

We’ve been using SHINING 3D’s product for years now, and it’s been a game-changer for our clinic practice. It’s helped us go digital, get rid of the messy impression material, and work more efficiently than ever before.

ENG

ENG