Dental 3D Printing

Personalized dental restorations rely on high-quality dental 3D printing technology. It is typically combined with intraoral scanners that capture the patient’s dental structure, allowing dentists to quickly customize crowns, dental bridges, implants, and orthodontic appliances that precisely match the patient’s oral structure, making the treatment process more time-saving and convenient.

In this article, we’ll explore 7 major applications for 3D printing as well as advanced dental printing solutions. Keep reading to learn more.

About Dental 3D Printing

What is Dental 3D Printing?

Dental 3D printing, also known as additive manufacturing, is a technology that builds 3D dental appliances and models layer by layer by adding materials based on digital models.

Among these, the digital models come from intraoral scanners. They can obtain a 3D image of the patient’s oral cavity through scanning within minutes and convert it into CAD data for creating dental restorations.

Machines for Dental 3D Printing

A complete dental 3D printing setup requires the use of dental 3D printers and dental curing lights:

· Dental 3D Printer: It prints resin or ceramic materials into dental appliances or models. Equipped with high-precision print heads and control systems, it ensures consistent quality of the printed restorations.

· Light Cure Unit: The printed resin components require curing under UV light to enhance the mechanical strength of the material. Dental light cure units are crucial for ensuring the durability, stability, and consistency of the final product.

7 Applications of Dental 3D Printing

The 7 applications for 3D printing include crowns and bridges, dentures, implants, aligners and retainers, jaw and oral models, casting patterns, and surgical guides.

1. Crowns and Bridges

Dental crowns and bridges are restorations that cover teeth to restore their appearance and strength. They are commonly used to treat severe tooth decay, fractures, or teeth that have undergone root canal treatment.

Dental 3D printing enables dentists to quickly produce customized crowns and bridges. Their shapes can be created from digital impressions, reducing turnaround time while ensuring a precise fit.

2. Dentures

Dentures are designed to mimic the functions and appearance of natural teeth, improving patients’ chewing ability and aesthetics. However, the traditional denture fabrication process is relatively complex and requires multiple patient visits.

3D printer for dental leverages digital workflows to produce dentures quickly and directly while precisely controlling the occlusal surfaces to ensure proper bite alignment.

3. Implants

Implants are used to replace missing teeth, consisting of an artificial root implanted into the jawbone and a crown attached to the implant.

Dental 3D printing can produce surgical guides, 3D printed dental implants, crowns, and pre-surgical planning models. With its rapid printing speed, it ensures quick production of durable and precise restorations, meeting the most demanding dental requirements while avoiding treatment delays.

4. Aligners and Retainers

Aligners and retainers are used to correct tooth alignment and occlusion issues, as well as to maintain tooth positions after treatment. Orthodontic treatment has greatly benefited from dental 3D printing technology, particularly for Invisalign, which requires frequent replacement. This technology not only accelerates production speed but also enhances fitting accuracy through high-precision digital impressions.

Moreover, 3D printing in orthodontics eliminates the need for physical dental molds when fabricating aligners and retainers, significantly reducing turnaround time and improving clinic efficiency.

5. Jaw and Oral Models

Jaw and oral models help dentists diagnose jaw abnormalities, plan jaw surgeries, or prepare for dental implants. Detailed observation of jaw and oral structures through these models can effectively reduce the risk of procedural errors.

Traditional model fabrication involves creating plaster casts first, then mounting dentures—a process that consumes time and labor. However, with dental 3D printing solutions, dentists can produce customized models for different patients, significantly improving treatment efficiency.

6. Casting Patterns

Casting patterns are used to fabricate crowns, bridges, and other fixed restorations. For cases involving metal appliances, 3D teeth printing can be employed to create wax or resin casting patterns, eliminating the need for patients to bite wax to create molds.

7. Surgical Guides

Custom surgical guides are essential for complex procedures such as jaw surgeries and dental implant placement. 3D-printed surgical guides ensure precision, reduce operative time, and reduce the risk of complications due to improper implant positioning.

Dental 3D Printers and Light Cure Units from SHINING 3D Dental

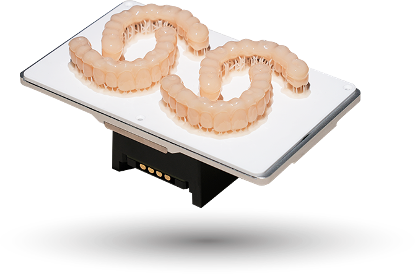

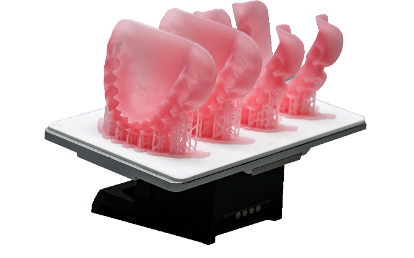

Whether fabricating crowns, dentures, or orthodontic appliances, high-performance dental 3D printers, and light cure units are essential for enhancing clinic efficiency. In this regard, the AccuFab-F1 and FabCure N2 from SHINING 3D Dental are specifically designed for dental professionals, delivering exceptional precision and stability.

Our AccuFab-F1 produces high-quality restorations suitable for all-on-X cases. It maintains consistent printing quality even with high-viscosity resins.

The FabCure N2 utilizes 365nm UV light to unlock superior material properties. Equipped with an automated nitrogen system, it delivers smooth, tack-free components. Its precision temperature control accelerates curing time without compromising material quality. The FabCure N2 is compatible with all dental restorations.

Conclusion

Dental 3D printing technology is reshaping the future of dental care, bringing revolutionary breakthroughs in restorations, implants, and orthodontics. If you are finding ways to enhance clinical efficiency, contact SHINING 3D Dental now for innovative dental 3D printers and light cure units!

.jpg)