Table of Contents

In dental implantology, precision and reliability are crucial to successful outcomes. At SHINING 3D DENTAL, we recognize the growing importance of 3D printer for dental implants in supporting dental professionals to achieve consistent and accurate results. The use of 3D printing technology in implant production is changing the way implant components are manufactured and prepared for clinical use. Here, we explore how 3D printers contribute to implant dentistry and the benefits they bring to dental practices and labs.

Precision in Implant Component Fabrication

One of the key advantages of using a 3D printer for dental implants is the high level of precision it offers. Implant components such as surgical guides, abutments, and frameworks require exact measurements to ensure proper fit and function. Traditional manufacturing methods can introduce slight variations that may affect implant placement or stability.

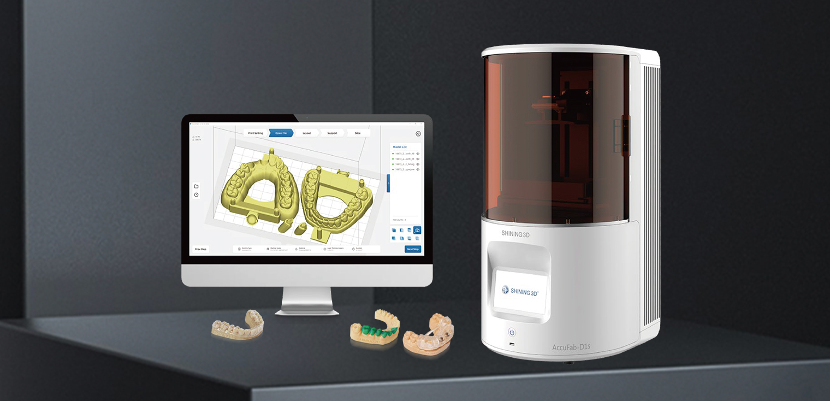

With SHINING 3D DENTAL printers, dental professionals can produce implant parts with fine detail and accuracy. Our printers feature advanced motion control and uniform light exposure to create components that closely match digital designs. This accuracy helps dentists place implants more confidently, improving integration with the jawbone and reducing the risk of complications.

Streamlined Workflow from Design to Production

The implant production process involves multiple steps, from scanning and digital design to printing and post-processing. 3D printing integrates smoothly into this workflow, enabling dental labs and clinics to move from a digital model directly to a physical product without intermediate manual steps.

SHINING 3D DENTAL offers printers that are compatible with various dental materials suitable for implant components. This flexibility allows dental professionals to select the right material based on strength, biocompatibility, and specific clinical needs. Additionally, the integration of automated post-processing devices reduces labor time and ensures consistent quality in the final product.

Enhanced Clinical Outcomes and Efficiency

The precision and reliability offered by 3D printing contribute to better clinical outcomes for patients receiving dental implants. Surgical guides produced with 3D printers assist surgeons in accurate implant placement, which is essential for long-term success. The ability to produce implant components on demand also shortens turnaround times, allowing for faster treatment plans and reduced patient wait times.

At SHINING 3D DENTAL, we understand that efficiency is vital in dental practices. Our 3D printers support high-resolution printing at fast speeds, making it possible to meet the demands of busy clinics and laboratories without compromising on quality.

Conclusion

3D printers for dental implants are becoming an integral part of modern dental workflows. By offering precise fabrication of implant components and streamlining production processes, these printers support dental professionals in delivering improved care. SHINING 3D DENTAL’s technology helps bridge the gap between digital design and physical products, contributing to efficient and accurate implant treatments. Embracing 3D printing in implant dentistry offers a practical approach to meet patient needs while maintaining high standards in dental manufacturing.

ENG

ENG